The Unseen Craft: Repairing the Flashforge Adventurer 3

The Unseen Craft: Repairing the Flashforge Adventurer 3

It was a typical afternoon in our quaint workshop, the air filled with the faint aroma of molten plastic and the rhythmic hum of machinery. That's when we received an urgent call from Jack, a long-time enthusiast and proud owner of a Flashforge Adventurer 3 3D printer. His voice was tinged with concern, a rare departure from his usual exuberant tone. His printer, a machine woven into the fabric of his creative endeavors, had ceased to print, leaving him with a mystery to unravel.

Jack brought the ailing adventurer to us, placing it carefully on our workbench. The issue at hand was elusive, the printer refusing to function without revealing an immediate cause. We exchanged thoughtful glances and rolled up our sleeves, ready to get to the root of the problem. Disassembly commenced, each screw and component meticulously cataloged as we navigated through the machine's intricate setup.

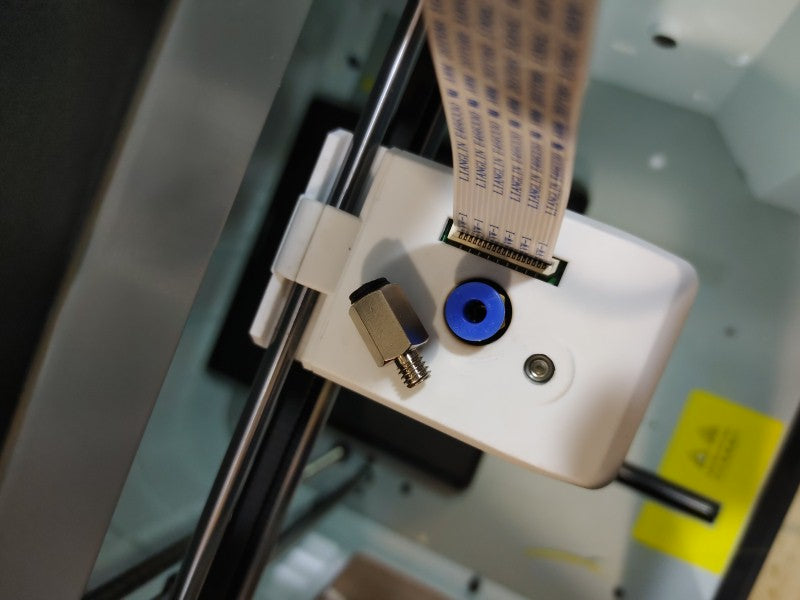

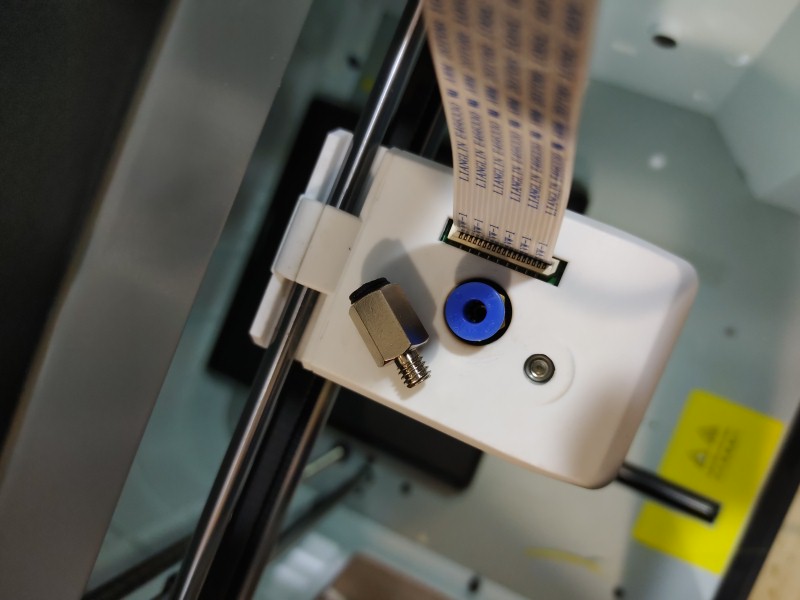

Embarking on the repair, we meticulously detached the hotend assembly, with a cautious yet decisive hand to avoid further damage to the machine's precise mechanics. As we carefully freed the hotend from its filament shroud, a more sinister layer of the problem unveiled itself. The pneumatic connector, a crucial component responsible for guiding the filament smoothly into the hotend, was severely damaged. This small but vital piece had put the entire operation to a halt, effectively blocking the filament and preventing any semblance of printing.

The realization hit hard; the age of Jack's printer rendered finding replacement parts a formidable challenge. Scouring online stores yielded no results, and even the original manufacturer could not provide the necessary components or digital blueprints to 3D print new ones. In that pivotal moment, we faced a crossroads: accept defeat and retire the piece or find an unconventional solution to breathe life back into this beloved machine.

Opting for the latter, we armed ourselves with nothing more than determination and a heat gun. The next phase was delicate, like performing a mechanical surgery of sorts. With carefully controlled heat, we reshaped the deformed plastic holder and mount. Despite the painstaking nature of the task, this was merely a precursor to our final solution: replacing the damaged pneumatic connector.

We located a suitable replacement part, one that promised compatibility and durability. After a careful swap and precision reassembly, the moment of truth arrived. With bated breath, we loaded the filament and initiated a new print. The extruder whirred, the familiar sound of material feeding through the nozzle filled the room, and the first layers of the 3D print began to emerge flawlessly.

The Flashforge Adventurer 3 was back in action, not just as a machine, but as a cherished companion to Jack's creativity. He hailed this rescue operation as nothing short of miraculous, and our team shared in his joy. It was a testament to the unrelenting spirit of repair and the love for machines that turn ideas into reality, proving that with perseverance, even the most challenging problems can be overcome.