Selling fast!

Get yours while you can.

From $3.00

Couldn't load pickup availability

Secure your shopping experience with various safe and trusted payment methods.

Product information for Mk10 Stainless Steel Nozzle

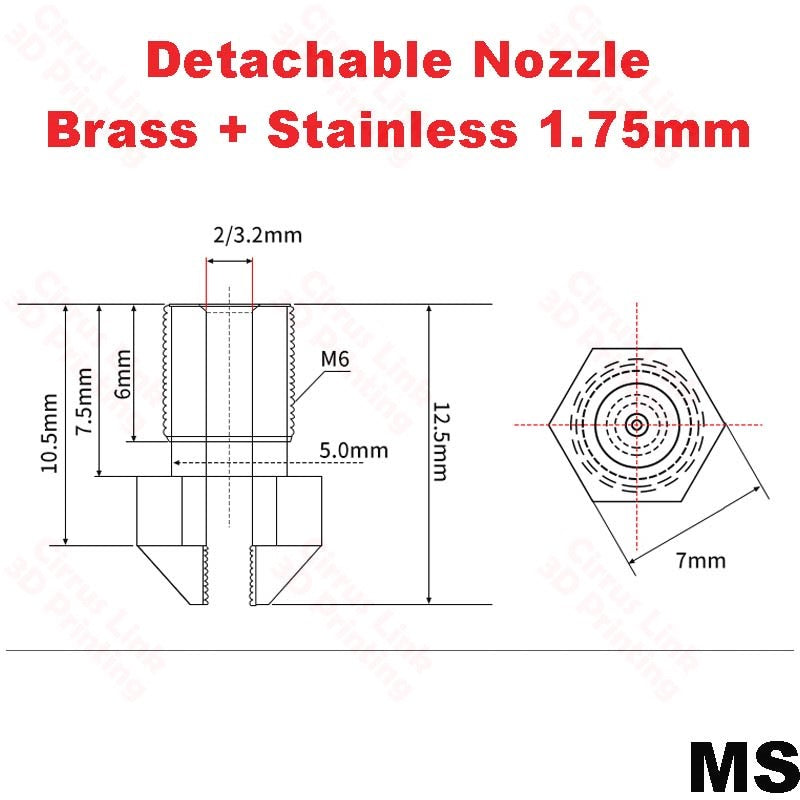

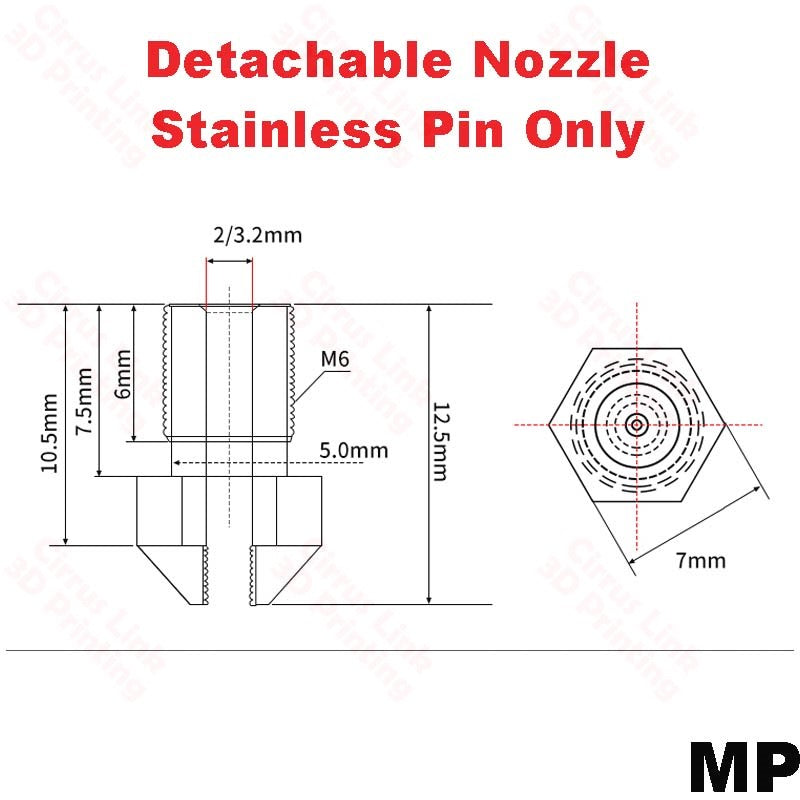

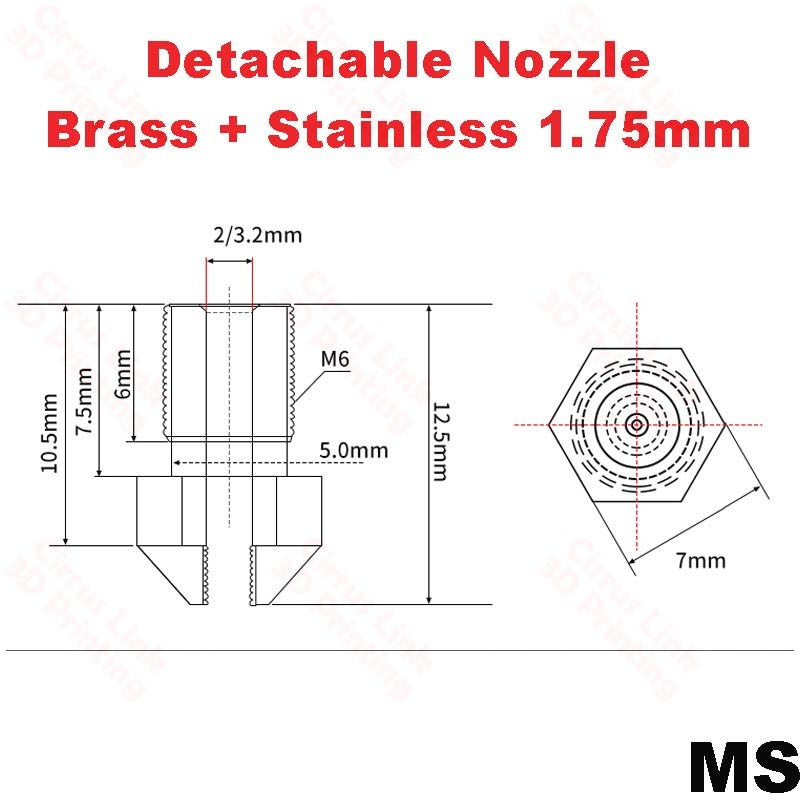

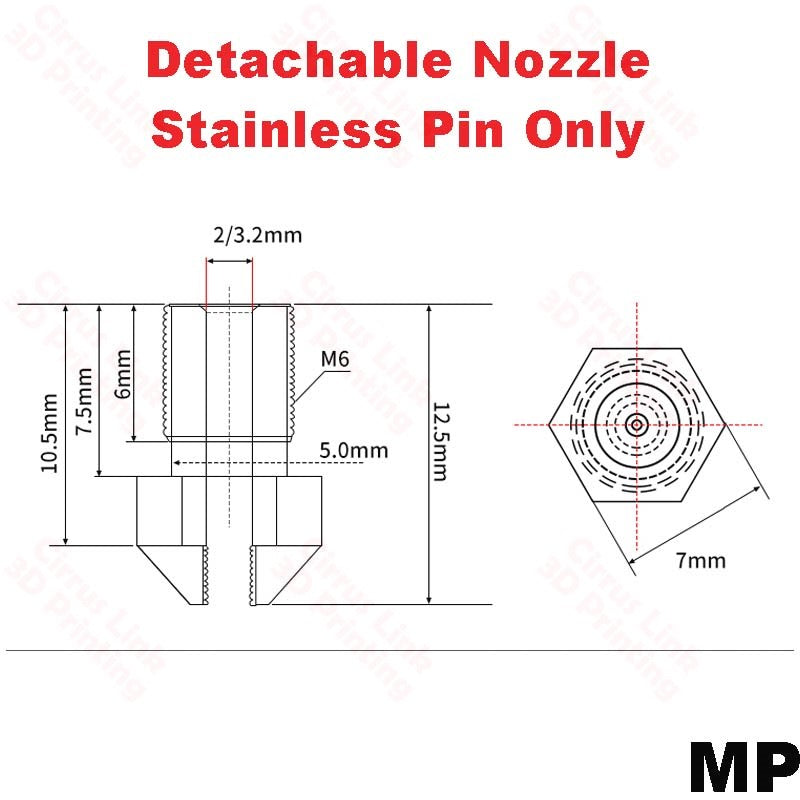

Model Name: MK10 Stainless Steel Nozzles

Material: Stainless Steel

Product Size: 13mm X 7mm

Inner diameter: 2.0mm, 3.2mm

Filament: For 1.75mm,3mm

Thread: M6

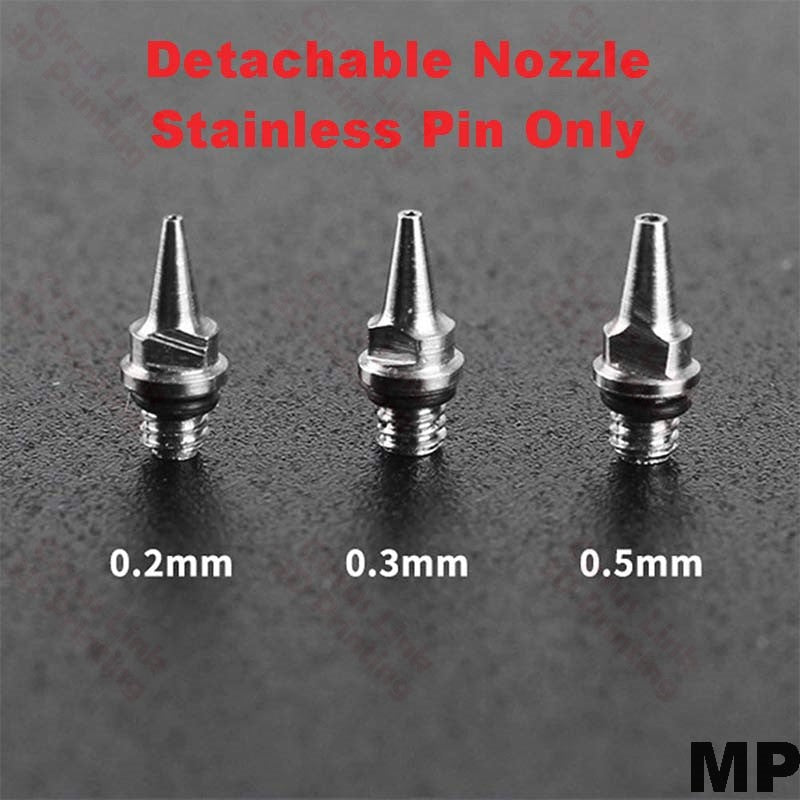

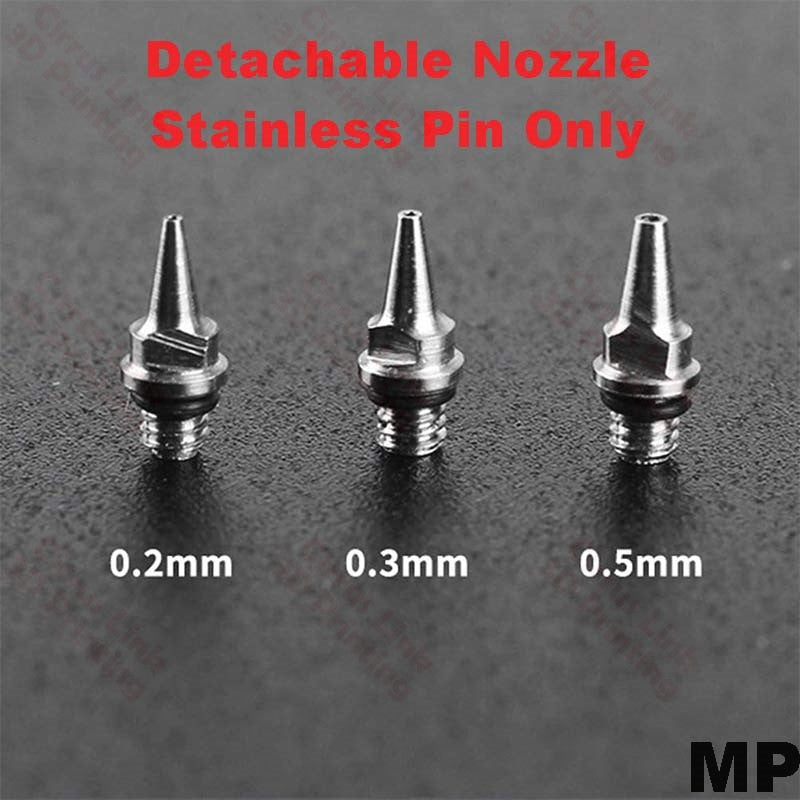

Nozzle diameter: 0.1mm/0.2mm/0.25mm/0.3mm/0.35mm/0.4mm/0.5mm/0.6mm/0.8mm/1.0mm

Package: 1 nozzle

These nozzles are compatible with many heating blocks and are perfect for products of the same size. Please note: If you have purchased a kit that contains this nozzle, it does not include the heating block. The nozzle is easy to remove and switch between 3D printers and it can be installed in 5 minutes. The nozzle will give you precision and consistency in your print.

The nozzle is made of brass, a material known for its high thermal conductivity, hardness, and durability. It is more durable than plastic and lighter than stainless steel, making it a great choice for nozzles. This set of nozzles has an optimized structure that improves the printing effect. The nozzles need to be as long and sharp as possible to better control the process.

The longer the nozzle, the further the distance between the heating block and the print. And the sharper it is, the less heat can affect printing. So we recommend you choose a nozzle with a suitable length. However, it is possible to choose a nozzle with a length that is too long for the printing area, resulting in uneven printing. In this case, we can use a nozzle fixer instead of changing the nozzle.

Our M6 thread products come in a variety of sizes to perfectly meet your needs. Whether you're looking for a product to use in a wide range of scenes or one specifically tailored to your needs, we've got you covered.

The longer the nozzle, the greater the distance between the printing bed and the printed model, minimizing the heat radiation to the printed model, improving print quality. The length and sharpness of the nozzle play a big role in how much heat is radiated onto the print. To minimize heat, the nozzle needs to be as long and sharp as possible, making the distance between the heater block and the print as large as possible. It is more practical and economical to pay a little extra for a hardened, wear-resistant nozzle. By the time you’ve printed a single spool of abrasive filament, you’re saving money. It also saves a lot of time, as you won’t be constantly replacing worn out nozzles. With its removable, pointed, steeless tips, it's easy to change. Nozzle tips in time when the filament blocks the tip of the nozzle.

Note: Before changing the nozzle tips, heat up the extruder to make the process easier.

At our Shopify store, we prioritize your safety and security. Here's how we ensure a secure shopping experience:

1. Secure Transactions: We use advanced encryption to protect your personal and payment information, ensuring it is safely transmitted and safeguarded.

2. Trusted Payment Gateways: Our store integrates with trusted payment gateways, ensuring your transactions are processed securely and efficiently.

3. Data Privacy: Your privacy is our top priority. We follow strict data protection policies to keep your personal information confidential and secure.

4. Secure Platform: Shopify provides robust security features and continuous monitoring against vulnerabilities, ensuring a safe shopping environment.

5. Verified Merchants: We are a verified merchant on Shopify, committed to providing authentic and high-quality products.

6. Transparent Policies: Our clear return, refund, and shipping policies provide peace of mind, knowing we stand behind our products.

7. Customer Support: Our dedicated customer support team is ready to assist with any concerns or questions you may have.

Shop confidently at our Shopify store, where your safety and satisfaction are our top priorities.

$7.50

Selling fast!

Get yours while you can.