Filament - Tronhoo PLA SILK 3D Printing Filament 1.75mm THPS

- Availability: in stock Many in stock Out of stock You can purchase this product but it's out of stock

- Vendor: TronHoo

Shipping

- Complimentary ground shipping within 1 to 7 business days

- In-store collection available within 1 to 7 business days

- Next-day and Express delivery options also available

- Purchases are delivered in an orange box tied with a Bolduc ribbon, with the exception of certain items

- See the delivery FAQs for details on shipping methods, costs and delivery times

Returns and Exchanges

- Easy and complimentary, within 14 days

- See conditions and procedure in our return FAQs

Have a question?

- Description

- Reviews

TronHoo was co-founded by a group of innovative minds that wanted to push the boundary of 3D printing technology in 2017. The company was started with a desire to innovate and focused on the latest technologies in material science, intelligent control, and mechanical engineering. The company started with gene of technology innovation and was aimed to push the boundary of 3D printing technology. In an effort to capture some of the buzz from Shenzhen's national event, TronHoo released their first 3D printer at the venue of 2018 national mass innovation and entrepreneurship week. This quickly garnered the attention of the public and became a best seller. After all, TronHoo's new product offered a variety of great features which had the potential to benefit the average person. Local mainstream media was quick to confirm the market prospect of the new product and ensured its success. Recognizing that market demand for its 3D printing filament was increasing, TronHoo realized that it needed to upgrade its production capacity to meet the increased demand. TronHoo's ten fully automated 3D printing filament production lines, two 3D printer inspection labs ensure production of 500,000 sets of 3D printers and 1,500 tons of 3D printing filaments export annually. TronHoo PLA Filament Perth Base available for selling now.

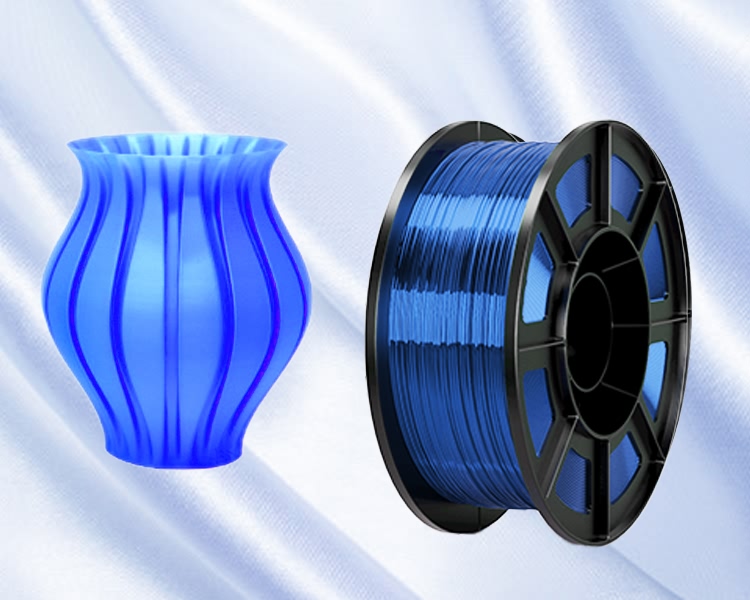

Print With Silk Surface

The PLA Silk has a bright luster and a smooth, silky texture, making it a great choice for those who want the best of both worlds.

Environmental Friendly

This food-grade and environmentally-friendly material is extracted from corn or other plants. It is safe, odourless, and degradable, and poses no harm to health.

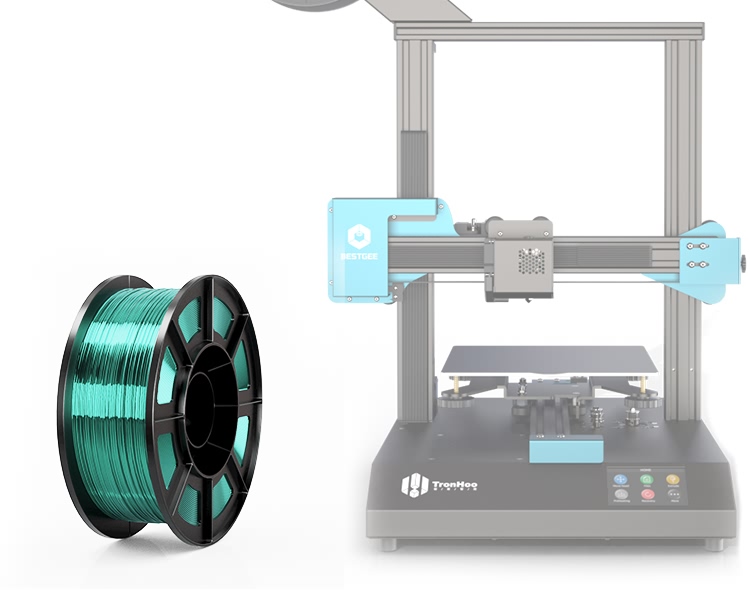

High Compatibility

Widely used in 3D printing, our filament is suitable for 99.99% of FMD/FFF 3D printers. Easy to form and with a great printing effect, it's the perfect choice for your next project!

Avoid filament breakage

This products boast good toughness, tensile strength and liquidity. We conduct strict quality control for each batch to ensure 100% no bubble and good printing effect without warping.

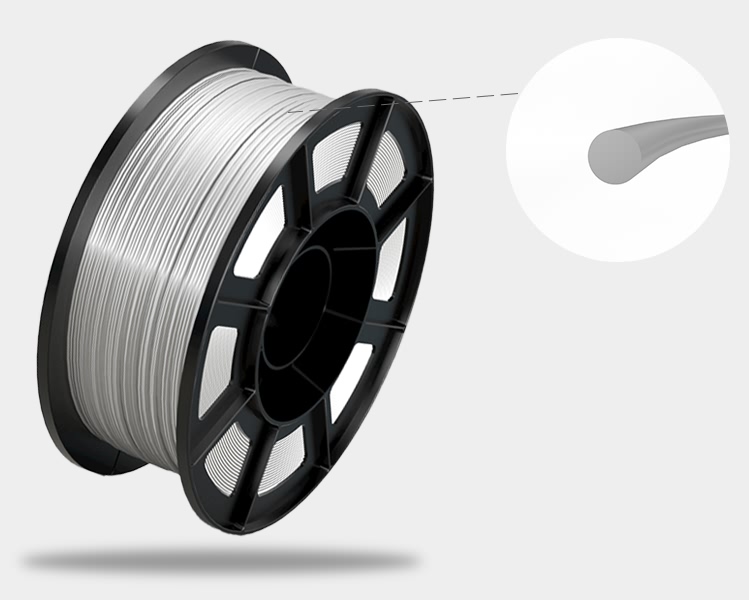

High Precision of Diameter

The tolerance of filament diameter is controlled within ± 0.02mm, ensuring stable and even extrusion for high printing accuracy and quality.

| Diameter | 1.75 ± 0.2mm |

| Printing Temperature | 175-200℃ |

| Heated Bed Temperature | 50-80℃ |

| Density | 1.25 ± 0.05 g/cm3 |

| Heat Deflection Temperature | 50-60℃ |

| Melt Flow Rate | 5-7 g/min (190℃ 2.16kg) |

| Tensile Strength | ≥ 60 Mpa |

| Bending Strength | ≥ 70 Mpa |

| Elongation at Break | ≥3.0% |

| N.W. | 1.0 kg |

| G.W. | 1.3 kg |

| Length | ≈ 330m |