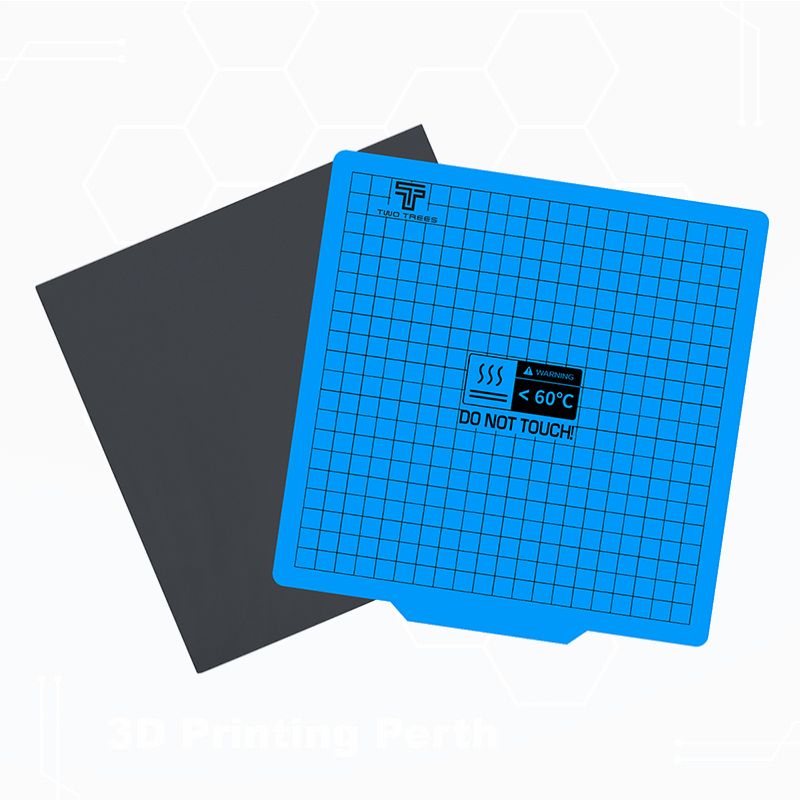

Build Platform Flexible Film Magnetic Plate Anti-Warping for Hot Bed (Blue)

- Availability:Out of stock

- Vendor: OpenBuild

Shipping

- Complimentary ground shipping within 1 to 7 business days

- In-store collection available within 1 to 7 business days

- Next-day and Express delivery options also available

- Purchases are delivered in an orange box tied with a Bolduc ribbon, with the exception of certain items

- See the delivery FAQs for details on shipping methods, costs and delivery times

Returns and Exchanges

- Easy and complimentary, within 14 days

- See conditions and procedure in our return FAQs

Have a question?

- Description

- Reviews

Looking for a way to keep your 3D printer stable and free from warping? Look no further than our Build Platform for 3D Printer Flexible Film Magnetic Plate Anti-Warping. This platform is designed to fit most 3D printers and is made of two layers of high-quality magnetic material. This will ensure that your print will remain stable and free from warping.

Our magnetic plate also features a double layer design that ensures a strong and durable connection between the printer and the platform. This will help to prevent your printer from moving and causing issues with your prints.

Our Build Platform is also resistant to high temperatures, making it ideal for use with 3D printing materials that require a high temperature tolerance. This platform is also easy to pickup and manual in operation, making it perfect for use with low-cost or manual 3D printers.

Order your Build Platform for 3D Printer Flexible Film Magnetic Plate Anti-Warping today and keep your 3D printer stable and free from warping.

Specifications:

Product: Double-Layer Magnetic Build Plate

Dimensions 210mm X 210mm , 235mm X 235mm , 310mm X 310mm

Thickness: 1.8mm

Color: Blue

Compatibility: Hot bed temperature not exceeding 60°C or cold bed printing

Features:

-Strong magnetic polarity corresponding to any direction

-Printing matte layer with strong adsorption force that prevents edge warping

-Fixed layer that is durable and does not need to be replaced

-Excellent toughness

Installation/Use:

-Tear off the adhesive on the back of side B and the protective film on the front

-Stick it directly on the platform

-Attach side A to side B

-Re-level it to print

Instructions

A microporous frosted skin texture treatment on the adsorption layer allows the hot-melt material and printing layer to fuse together effortlessly, minimizing distortion and warping. This increased adhesion gives consumables added suction during printing, and when the temperature drops, the adhesive strength decreases, making it easy to remove.

A high thermal conductivity iron-based alloy known as carbide layer is employed to render the platform smooth and level. Iron can additionally be fused to any side of the magnet, thus broadening the compatibility scope for different consumables.

Tips:

To ensure the longevity of the surface sheet, use a spatula or putty knife with smooth/rounded corners. Avoid using solvents, such as acetone, to clean it.

Typically with other build surface solutions, such as blue masking tape or polyimide, a heavy deposit or “smoosh” is used on the first print layers.

For optimal edge warping, it's best to keep the heat bed temperature below 50°C. If your printer doesn't have a heat bed, adjust the feed rate - 17 for the first layer and then gradually increase it with each successive layer.

Before operating, make sure that the machine is leveled. If not, proceed with caution when placing your order.

Do not press the hot nozzle onto the surface. Make sure to take out the mould promptly after printing and not wait until the next day; otherwise, the mould will stick firmly to the printing surface, making it hard to remove and reducing the lifespan of the bed.

If it is discovered that the initial layer isn't adhering during use, this is likely due to the fact that the third-party machine and material platform used are not leveled. With the various machines and consumables manufacturers out there, each having their own design structure and printing temperature, it's impossible to test them all. Therefore, it is essential to self-test the most appropriate temperature and adjust the parameters to get the most accurate real shot versus printed product display.