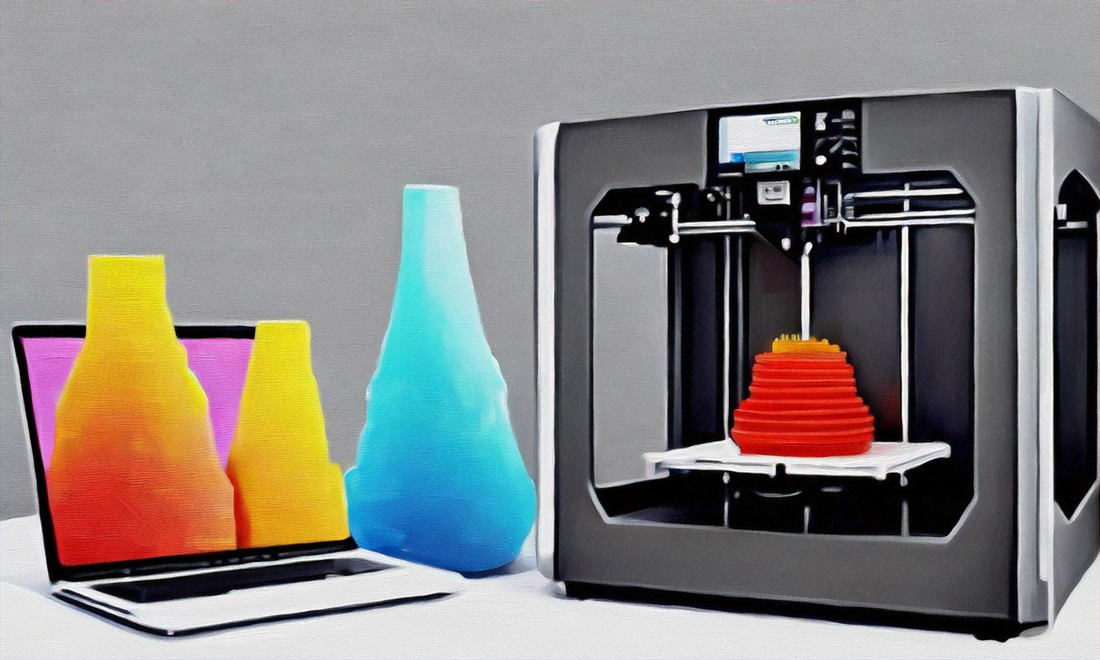

Unlocking Competitive Edge: Long-term Benefits of 3D Printing

In the ever-evolving landscape of manufacturing and beyond, one disruptive technology continues to pave the way for long-term benefits across various industries: 3D printing. Imagine a world where customized solutions, precise medical devices, and competitive product differentiation are not just possibilities but realities. This blog delves into the transformative power of 3D printing and its profound impact on driving sustainable growth, innovation, and efficiency in diverse sectors. Join us as we explore the endless possibilities and lasting advantages that 3D printing offers to businesses and industries worldwide.

Exploring the Sustainable Advantages of 3D Printing

Reduced Material WasteThe adoption of 3D printing technology in various industries holds significant potential for reducing material waste. Traditional manufacturing processes often generate excess material that goes unused, leading to inefficiencies and increased costs. With 3D printing, materials are used more selectively, minimizing waste and promoting sustainability in production operations.

Energy EfficiencyEmbracing 3D printing can contribute to enhanced energy efficiency within manufacturing processes. Unlike conventional manufacturing methods that may require substantial energy consumption, 3D printing often involves lower energy inputs due to additive manufacturing techniques. This results in reduced environmental impact and long-term cost savings for businesses.

Environmentally Friendly Practices3D printing offers environmentally friendly practices that align with the growing emphasis on sustainability across industries. By enabling localized production and on-demand manufacturing, organizations can lessen reliance on global supply chains, diminishing carbon footprints associated with transportation and logistics. Incorporating 3D printing technologies fosters eco-conscious strategies and promotes a greener approach to production.

Key Benefits Includes:

Minimized material waste

Reduced energy consumption

Promotion of sustainable manufacturing practices

Incorporating sustainable approaches through 3D printing not only enhances operational efficiency but also underscores a commitment to long-term benefits for businesses and the environment. By leveraging the sustainable advantages of 3D printing, industries can drive positive change while securing competitive advantages in the marketplace.

Enhancing Operational Efficiency and Cost Savings

On-Demand ManufacturingThe implementation of 3D printing technology in diverse industries facilitates on-demand manufacturing capabilities. Companies can produce parts and products precisely when needed, reducing inventory costs and streamlining production workflows. This agile approach to manufacturing ensures optimal resource utilization and eliminates excess stockpiles, leading to significant cost savings and operational efficiency gains.

Simplified Supply Chain3D printing enables a paradigm shift in supply chain management by simplifying traditional logistical processes. With the ability to fabricate components locally, organizations can minimize dependence on external suppliers and mitigate risks associated with global supply chain disruptions. By shortening lead times and enhancing production flexibility, businesses can respond more effectively to market demands while cultivating resilience in their operations.

Reduced Production Time and CostsOne of the enduring benefits of 3D printing in various industries is the reduction in production time and associated costs. Unlike conventional manufacturing methods that involve complex tooling and lengthy setup processes, 3D printing offers rapid prototyping and direct manufacturing capabilities. This accelerated production cycle not only expedites time-to-market but also optimizes resource utilization, driving down overall production expenses.

Key Benefits Includes:

On-demand manufacturing capabilities

Streamlined supply chain management

Accelerated production cycles and cost efficiencies

By leveraging the operational efficiencies and cost-saving advantages of 3D printing technologies, businesses can revolutionize their production strategies and achieve sustainable growth in competitive markets. Embracing these transformative capabilities positions industries for long-term success and profitability in the ever-evolving landscape of modern manufacturing.

Improving Product Customization and Innovation

Tailored Solutions for Diverse IndustriesThe versatility of 3D printing technology empowers industries to create customized solutions that cater to specific requirements across various sectors. From personalized medical devices to bespoke automotive components, 3D printing allows for the production of unique products tailored to individual needs. This level of customization not only enhances customer satisfaction but also fosters innovation and ingenuity in product design.

Rapid Prototyping for Iterative DesignOne of the key advantages of 3D printing lies in its ability to facilitate rapid prototyping and iterative design processes. By quickly generating physical prototypes, companies can iterate on product designs, test functionalities, and make informed refinements at a rapid pace. This iterative approach accelerates the product development cycle, reduces time-to-market, and promotes continuous innovation in product design.

Enhanced Product Performance and FunctionalityEmploying 3D printing technologies enables businesses to enhance product performance and functionality through advanced manufacturing techniques. By leveraging intricate geometries and lightweight structures that are challenging or impossible to achieve with traditional methods, industries can optimize product performance and functionality. This results in superior products that surpass industry standards and meet evolving consumer demands.

Key Benefits Includes:

Customized solutions for specific industry needs

Accelerated product development through rapid prototyping

Improved product performance and functionality

Embracing the capabilities of 3D printing for product customization and innovation empowers industries to stay ahead of the curve in a competitive market landscape. The ability to tailor solutions, iterate designs efficiently, and optimize product performance underscores the long-term benefits of integrating 3D printing technologies into diverse industries.

Boosting Competitive Edge in Manufacturing and Production

Increased Flexibility and AgilityThe adoption of 3D printing technologies offers industries increased flexibility and agility in their manufacturing and production processes. With the ability to quickly pivot between different designs and production runs, companies can respond swiftly to market demands and changing consumer preferences. This agility allows businesses to stay ahead of competitors and adapt to dynamic industry landscapes with ease.

Faster Time-to-Market3D printing accelerates the time-to-market for new products by streamlining prototyping and production timelines. Traditional manufacturing methods often involve lengthy lead times for tooling and production setup, leading to delays in product launches. In contrast, 3D printing enables rapid prototyping and on-demand manufacturing, reducing the time required to bring products to market. This expedited process enhances competitiveness and positions businesses for success in fast-paced industries.

Competitive Product DifferentiationThe advanced capabilities of 3D printing technology enable industries to achieve competitive product differentiation through innovative design and functionality. By leveraging the intricate designs and complex geometries achievable with 3D printing, companies can create unique products that stand out in the market. This differentiation not only captivates consumers but also establishes brand identity and market positioning, leading to long-term competitive advantages.

Key Benefits Includes:

Enhanced flexibility and responsiveness to market dynamics

Reduced time-to-market for new product launches

Competitive differentiation through innovative design capabilities

By harnessing the benefits of 3D printing in manufacturing and production, industries can boost their competitive edge and achieve sustainable growth in today's rapidly evolving business environment. The enhanced flexibility, faster time-to-market, and unique product offerings enabled by 3D printing technologies are instrumental in securing a prominent position in competitive industries.

Revolutionizing Healthcare with 3D Printing Technology

Patient-Specific Medical DevicesThe utilization of 3D printing technology in the healthcare sector has revolutionized the production of patient-specific medical devices. From custom prosthetics to personalized implants, 3D printing enables the creation of tailored solutions that match the unique anatomical requirements of individual patients. This customization results in enhanced comfort, functionality, and improved patient outcomes in medical treatments.

Precision Medicine AdvancementsAdvancements in precision medicine are facilitated by the precision and accuracy offered by 3D printing technology. The ability to create intricate models and structures with high precision allows for precise anatomical replicas for surgical planning and training purposes. This advancement in precision medicine enhances diagnostic accuracy, treatment efficacy, and patient safety within the healthcare industry.

Improved Surgical Procedures and Outcomes3D printing technology has transformed the landscape of surgical procedures by facilitating preoperative planning, patient-specific instrumentation, and anatomical models. Surgeons can now visualize complex anatomical structures in 3D, practice surgeries on accurate models, and tailor surgical approaches to individual patients. This level of precision and customization leads to improved surgical outcomes, reduced surgical times, and enhanced patient recovery rates.

Key Benefits Includes:

Customized patient-specific medical devices

Enhanced precision medicine through accurate modeling

Improved surgical outcomes and patient safety

The integration of 3D printing technology in healthcare demonstrates the profound impact it has on patient care, surgical procedures, and medical advancements. By leveraging the benefits of 3D printing, healthcare providers can deliver personalized treatments, optimize surgical interventions, and ultimately improve the overall quality of patient care in the long run.

FAQ Section

### How can 3D printing benefit small businesses in different industries?Small businesses can leverage 3D printing to reduce prototyping costs, customize products for niche markets, and enhance production flexibility. By embracing this technology, small enterprises can compete with larger counterparts, drive innovation, and adapt to changing market demands more efficiently.

### Are there specific industries that have seen significant success with 3D printing adoption?Industries such as aerospace, healthcare, automotive, and consumer goods have experienced remarkable success with 3D printing implementation. From lightweight aerospace components to patient-specific medical devices, 3D printing has revolutionized manufacturing processes and product development in these sectors.

### What are the long-term environmental benefits of incorporating 3D printing into industrial practices?Long-term environmental benefits of 3D printing include reduced material waste, lower energy consumption, and sustainable manufacturing practices. By minimizing waste and optimizing resource utilization, 3D printing contributes to eco-friendly production processes and promotes environmental sustainability.

### How does 3D printing contribute to product innovation and customization?3D printing enables product innovation and customization by allowing for intricate designs, rapid prototyping, and tailored solutions. Companies can create unique products, iterate designs quickly, and cater to individual customer needs, fostering creativity and differentiation in the market.

### What role does 3D printing play in the future of manufacturing across different sectors?The future of manufacturing across various sectors is heavily influenced by 3D printing technology. From on-demand production to personalized healthcare solutions, 3D printing will continue to drive efficiency, cost-effectiveness, and innovation in manufacturing processes, shaping the industry landscape for years to come.