Find Out Why Leveling is Essential for 3D Printing Success!

3D printing is an incredible technology that is revolutionizing the way we think about manufacturing and product design. However, it is important to remember that 3D printing is a complex process that requires a great deal of precision in order to produce quality results. One of the most important aspects of this precision is the leveling of the 3D printer’s build platform.

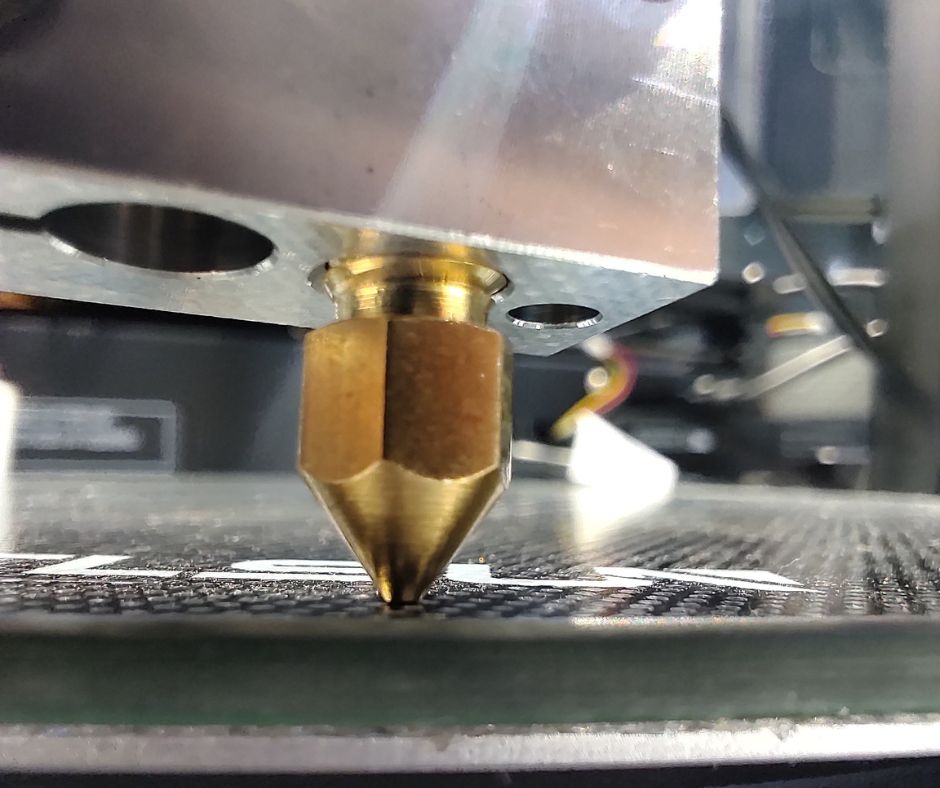

Leveling the build platform is essential for ensuring that the print head of the 3D printer moves smoothly over the surface of the build platform. If the platform is not level, then the print head will have difficulty moving over the uneven surface, resulting in inconsistent prints. Additionally, if the build platform is not level, then the printed parts may not adhere properly to the platform, leading to warping or delamination of the part.

In addition to ensuring the quality of the prints, proper leveling of the build platform is also necessary for ensuring the safety of the 3D printer. If the build platform is not level, then the print head may be forced to move at an angle, which can cause it to crash into the platform. This can damage the print head, as well as the platform itself. Leveling the build platform helps to prevent these types of accidents from occurring.

Finally, leveling the build platform is important for achieving consistent results with each print. If the platform is not level, then the first layer of the print may be thicker in some areas than others, resulting in an uneven finish. This can be especially problematic for parts that require tight tolerances, such as those used in engineering or medical applications.

Overall, it is clear that leveling the build platform of a 3D printer is essential for achieving quality prints, preventing accidents, and achieving consistent results. While it may seem like a tedious task, it is an important step in the 3D printing process that should not be overlooked. With proper leveling, you can ensure that your 3D prints come out looking their best every time.