Navigating the Perilous Path of 3D Printing Safety: A Comprehensive Guide

Introduction

Imagine standing on the precipice of technological marvel yet being shackled by something as primal as safety. Skirting this paradox is the world of 3D printing, a realm of creation that merges the complexities of design with the intricacies of manufacturing, both held together by the thread of security. In the midst of this 21st-century crafting revolution, lies an often-understated aspect - safety. Flickering in the shadowy corners of this innovative journey, it whispers warnings that might spell the difference between wonderment and regret.

3D printing, or additive manufacturing, has sprinted from the realms of science fiction into the hands of hobbyists and innovators worldwide. It gives wings to our wildest ideas, transforming them into tangible realities. From intricate jewelry to custom prosthetics, architectural models to actual edible chocolate, the possibilities seem endless. This spectacular invention, however, is not without its perils. Like every engineering feat, it demands respect for its inherent risks alongside admiration for its capabilities.

Now, let us traverse the labyrinth of 3D printing safety. Like seasoned mountaineers braving an untamed landscape, we shall climb the summit one step at a time. Each stride will unravel a new layer of understanding, and each pause will bring valuable insights into the potential risks and responsible practices associated with 3D printing. Our quest aims to arm you with the knowledge necessary to wield this impressive tool effectively, safely securing its boundless benefits while sidestepping its concealed threats.

Ventilation is Crucial

The world of 3D printing is a treasure trove of untold innovations and captivating creations. But like any form of alchemy, it carries its unique set of hazards. Among these, the invisible yet insidious peril of poor ventilation often gets overlooked. It's akin to inviting a silent assassin into your workspace. The first crucial step towards ensuring users' safety lies in understanding and respecting the importance of proper ventilation.

Imagine a panoramic studio with large windows, permitting gentle zephyrs to drift in, carrying away the by-products of your creative enterprise. This isn't just an idealistic vision but a primary requirement while operating a 3D printer. Employing a well-ventilated area ensures that you're not exchanging your health for innovation. This fundamental precaution is as indispensable as the printer itself.

What necessitates this acuity towards airflow? As enchanting as it is, 3D printing, unfortunately, includes a less glamorous side - the emission of potentially harmful fumes. These are not your average run-of-the-mill odors, mind you. Some printing materials, when subjected to heat, can emit fumes that, in enclosed spaces, create an environment equivalent to a smoke-filled chamber. The difference - because these fumes are often colorless and odorless, you may unknowingly inhale them, inviting unwanted health risks.

Consider the common 3D printing material, ABS plastic. When heated, ABS can produce styrene – a pungent-smelling compound, which, upon consistent exposure, can cause headaches, fatigue, dizziness, and even more serious health concerns. Similarly, other materials, like Nylon, when melted, release caprolactam, irritating the eyes and respiratory system. Hence, it's vital to remember when we unleash the magnitude of 3D printing, that we also fling open the window. A well-ventilated room acts like a vigilant guardian, extracting these harmful fumes and replacing them with clean, breathable air.

The beauty of 3D printing lies in its power to transform mere filaments into fantastic creations. But when these creations begin to compromise the creator's well-being, it becomes essential to navigate this precarious path with caution, the cornerstone being effective ventilation. When we incorporate safety practices like sufficient ventilation, we ensure that our journey in the magical realm of 3D printing doesn't lead us down a path of health hazards.

Beware of High Temperatures

Just as a chef respects the roaring flames of a professional kitchen, so too must a 3D printing enthusiast be acutely aware of the searing temperatures at play. Akin to an unsung hero, the printer's nozzle and heated bed hold the power to wield molten plastic into mesmerizing creations. But with this power comes immense heat - a potentially hazardous element of 3D printing that demands our full attention.

The humble 3D printer is a symphony of precision engineering, its components functioning in harmony to recreatemeticulously detailed designs from digital blueprints. At the heart of this spectacle, the printer's nozzle and heated bed are comparable to the fiery core of a star, infused with intense heat equivalent to the temperature of boiling water or even more. Such high temperatures are indispensable for melting the plastic filament, enabling it to flow and solidify gracefully into the desired form; but they also present a potential danger that should not, under any circumstances, be overlooked.

Imagine laying your hand on a scorching summer pavement, the heat pressing relentlessly against your skin. Such is the burn one could experience from carelessly touching the heated parts of a 3D printer prematurely, before they've had a chance to cool down. Just as you wouldn't dare to grab a sizzling cast-iron pan straight from the oven without protective mitts, you should likewise permit the printer's nozzle and heated bed ample time to cool after operations cease. This measure might seem like a trivial inconvenience in the face of bubbling excitement, but the patience required pales in comparison to the agony of a severe burn injury.

However, it's not only about direct contact. Be wary about the atmosphere around these heated components, soundlessly radiating waves of heat outward, which can potentially ignite flammable materials left carelessly near the printer. Keep in mind, 3D printing is less of an impassive activity and more of a commitment, requiring astute attention to detail and the constant vigilance of a watchful guardian.

To effectively navigate the perilous path of high temperatures in 3D printing, one must appreciate the power and potential danger that these heated components possess. With utmost reverence for the fiery heart of the 3D printer, you can guard against painful burns and prevent accidents before they occur. So remember, as you venture forth into the fascinating world of 3D printing, treat your equipment with respect, exercise diligence, and most importantly - beware of high temperatures.

Electrical Safety Matters

As we journey further down the path of 3D printing safety, the importance of mindful handling of its power supply and electrical components comes into sharp focus. Skirting around the heated dangers of nozzles and heated beds, we find ourselves at the heart of this machine - its electrical lifeblood. Imagine for a moment that our 3D printer is akin to a domesticated bolt of lightning, a contained thunderstorm buzzing with electric energy. It's wondrous, but it also holds a dangerous punch. It is the pulsating electricity that gives life to the machine, but mishandled, it can cause harm or even be fatal. Respect for this power is crucial.

Handle with Care

The dance with electricity must follow certain protocols. One should think of handling a 3D printer like cradling a newborn baby; tender, cautious, and very aware of its vulnerabilities. The power supply and electrical components should not be roughly handled or dropped, as even minor damage can have dire consequences - shocking, I know, both metaphorically and literally!

Dry Hands, Safe Hands

Picture this: your hands, a little damp from washing or the cold drink you were holding, now reaching out to the printer. Now, conjure up your high school science memories. Water is a great conductor of electricity, right? So that thin layer of moisture can turn your innocent touch into a perilous interaction. To maintain safety, ensure your hands are dry before getting close to the printer's electrical heart, as this simple step can mitigate the risk of electric shocks.

Power Off, Power Safe

Unceremonious interactions with a powered-on printer can resemble a particular type of Russian Roulette. Tempting fate by adjusting components while the device hums with electricity is a dangerous game that should never be played. Just as we wouldn’t stick a knife into an active toaster, it’s equally important to ensure the printer is turned off and unplugged before performing any adjustments or maintenance. This routine act of precaution diminishes the possibility of electrical injuries. Many may argue that these precautions towards electrical safety are basic; they're correct, yet it's shocking (pun intended) how often they're overlooked in the thrill of creating something new. One must remember that 3D printing, while a captivating harmonic dance of technology, can quickly transform into a capricious beast if safety measures are not respected. As we continue to navigate the intricacies of 3D printing safety, it's essential to remember that each warning sign is not a hurdle but rather a stepping stone guiding us towards the path of safe innovation. Remember, safety isn't just a precautionary measure; it's a way of life when dealing with 3D printers. END OF SECTION

Moving Parts and Pinch Points: A Dance of Danger and Dexterity

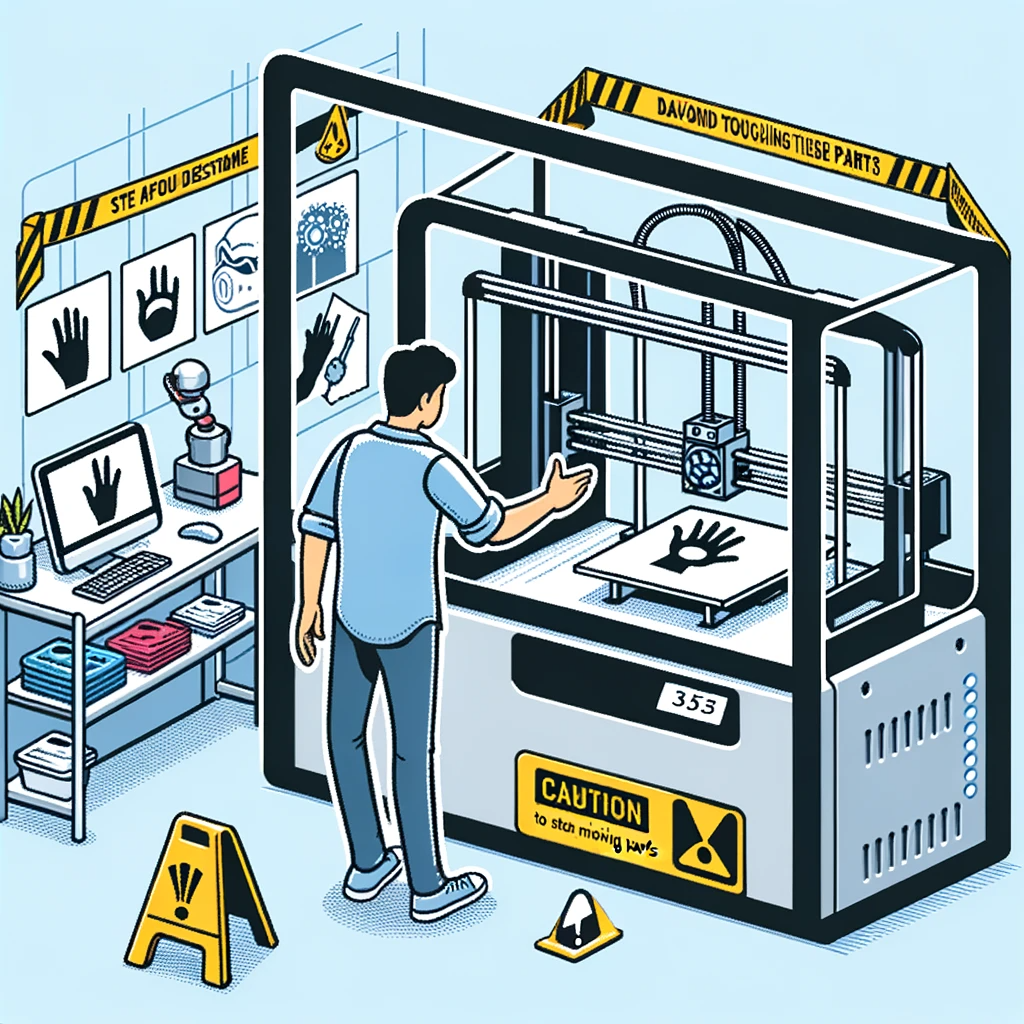

A 3D printer could be seen as a miniature factory, an embodiment of the industrial revolution in your very own workspace. And just like in any factory, there are moving parts that can pose potential dangers if not handled with caution. Picture the intricate ballet of gears, motors, and belts. The components work in harmony, a synchronized dance to assemble layers upon layers of filament, birthing three-dimensional creations. Yet within this beautiful symphony lies hidden peril.

Come too close, and you may find yourself drawn into the whirlwind of motion. Fingers, a moment ago poised in curiosity or awe, can suddenly become victims of the relentless mechanical dance. The importance of careful navigation around these kinetic elements cannot be overstated. A 3D printer, though a marvel of modern technology, is not a toy. It demands respect and requires vigilance.

Respecting The Dancers

Fingers, it is often said, are the tools of the trade. Regardless of whether you're an artist sculpting exquisite shapes from lumps of clay, a musician finessing the delicate keys of a piano, or a 3D printing enthusiast coaxing intricate models from spools of filament, your fingers play a crucial role. Therefore, preservation and safety of these tools should be prioritized.

Imagine standing on the edge of a dizzyingly fast carousel. You wouldn't dare try to touch or stop one of the carousel horses in motion, right? Now, apply the same analogy to your 3D printer's gears and motors. Respecting their motion ensures your safety and the precision of your print. This mindfulness is especially critical during the printer's operation, where moving parts are active and ready to bite the unwary.

Loose Ends: A Recipe For Disaster

While it is paramount to keep your digits safe, another consideration tops our list of safety guidelines - loose clothing and accessories. Just as a trailing scarf can get caught in the bicycle's wheel, so too can loose attire be ensnared by the printer's moving parts.

Earrings, necklaces, wristwatches, or even hanging drawstrings from your hoodie - they're all potential ticket holders for an unintentional ride on the 3D printer carousel. And, trust me, you do not want that ride. Therefore, adhering to a simple dress code when operating your printer could be what stands between you and a disastrous snap, crackle, or pop!

Can we ever be too careful with a 3D printer? Perhaps - but isn't it better to err on the side of caution than to pay the price later? Remember, every time you switch on that power button, you are directing a performance - one where recklessness has no place, and respect for the dancer's space is not just appreciated but vital. So, let the moving parts glide and groove, let the motors whir their melodious tune, but remember to keep safe, and never let curiosity lead you into the dance.

Material Handling

If you've come this far in the 3D printing world, you've probably heard about 'filaments.' Like the ink in a regular printer, filaments form the building blocks of your 3D printed masterpiece. However, unlike traditional ink, these printing materials are not universally interchangeable. In fact, treating them as such can not only damage your precious printer but also pose serious safety hazards.

The first rule of thumb is always to use recommended filaments for your specific printer model and follow the manufacturer's guidelines. This advice may sound mundane, but it carries weight heavier than the mightiest elephant. Your printer's manufacturer has designed it to work optimally with certain types of filaments. Ignoring this synchronization is like trying to fit a square peg into a round hole - it just doesn't work. Or worse, it ends in disaster.

Imagine you're tasked with cooking dinner, but instead of using fresh produce, you stubbornly decide to use expired ingredients. Even with the most luxurious kitchen equipment at your disposal, the dish is bound to turn out unpalatable and potentially harmful. Similarly, using unsuitable filaments hampers the integrity of your print output and increases risks, such as higher toxicity levels or printer malfunctions.

Furthermore, some materials demand special handling due to their unique properties. For instance, the popular ABS (Acrylonitrile Butadiene Styrene) filament emits an unpleasant smell when heated during the printing process. Yet, wearing a mask isn’t enough; adequate ventilation is equally critical. Contrastingly, PLA (Polylactic Acid), another commonly used filament, is made from renewable resources like sugarcane or cornstarch, making it more sustainable and less odorous. However, it's more susceptible to humidity, demanding careful storage practices.

From the outside, filaments might all look similar - like colorful spools of thread waiting to sew together your 3D-printed dreams. Yet beneath these swirling rainbows of plastic lie an orchestra of distinct chemical compositions that sing different tunes in the heat of the printer. Listening to these tunes by choosing the right filament and treating it correctly is not a luxury but a safety necessity.

To sum up, handling printing materials entails more than just picking a pretty color from the shelf. It involves understanding the manufacturer’s guidelines, the filament's special characteristics, and respecting their needs for safe and efficient printing. By recognizing these nuances, we take another firm step on the perilous path of 3D printing safety.

Fire Safety

Just as glowflies give off their soft, gentle light without scorching their surroundings, so too does the ideal 3D printer operate - with efficient, managed heat. However, missteps can occur. Electronic devices, despite their myriad benefits, harbor a rare but imperiling risk - they can, in certain circumstances, spark a fire.

Imagine this: the nozzle of your 3D printer, a concentrated sunspot of heat reaching temperatures akin to a baking oven, tirelessly crafting your design in intricate layers. The heated bed beneath it mirrors this intensity, fusing together the threads from the harshly glowing nozzle into a sturdy whole. A beautiful relationship of creation, wouldn't you agree? Now, add to this picture a small fault or disruption, a seemingly insignificant oversight, such as a sheet of paper too close to the heating elements, or a malfunctioning thermistor, and the consequence could be a fiery disaster.

In the world of 3D printing, vigilance is the cardinal virtue of safety. Never leave your printer unattended for extended periods during those trying lengthy prints. Believe me when I say no beautifully printed bust or architectural marvel is worth the risk of an unexpected fire. Keep your eyes trained on this magical construction site, anticipating and trouble-shooting any concerning situation that might arise.

But what if the unforeseen happens? What if the glowing ember of catastrophe flares up despite all precautionary measures taken? Well, herein lies the importance of a sturdy, dependable companion for every 3D printer operator - the fire extinguisher. This friend in red should always be within arm's reach, ready to quell any spark of danger which may threaten your printing haven. Just like a steadfast old bodyguard, it stands quietly at the sidelines, ready to protect its charge at a moment's notice.

In the heart of every craftsman lies an element of danger management, much akin to that adventurous spirit of a lion tamer, cautiously aware of its majestic yet perilous charge. 3D printing is the same. As it blossoms into a breathtaking spectacle of creation, it brings with it particular risks and responsibilities. However, only by navigating this perilous path, can we truly appreciate and revel in the sheer magic of birthing our designs from mere filaments and heat.

Remember, my fellow crafters, safety and preparedness are the twin pillars supporting the grand edifice of 3D printing. They ensure that the glorious light of creation continues unabated, without descending into the unpredictable flames of hazard. Let us embrace them, making safety a habit, not an afterthought, as we march forward on this exhilarating journey of creation.

Keep Your Workspace Organized

The pursuit of perfection in 3D printing is like navigating a labyrinth, filled with numerous infractions and hazards. Among them, one that often goes unnoticed yet injects chaos into the process is clutter. Grappling with a disordered workspace while getting indulged in the mesmerizing world of additive manufacturing can turn your magical journey into an unnerving ordeal.

The Chaos of Clutter

Clutter has an uncanny ability to evoke a sense of anxiety and stress, transforming the printing process into an arduous task rather than an artistic endeavor. A disorganized space, filled with scattered tools, filaments strewn haphazardly, and parts lying around, invites uncertainty, throwing off balance your workflow. It's like a slow poison, gradually eroding your efficiency, causing you to misplace essential components or overlook safety precautions. Imagine it as a dense fog obscuring vision, each scattered item adding to the haze, making tasks more time-consuming and taxing.

Embracing Order

Conquering the clutter is not just about tidiness; it’s about embracing order, installing a sense of calm and control in your workspace. Organizing your work zone is akin to composing a well-coordinated symphony with filaments, tools, and accessories playing their parts harmoniously. Each item is provided its designated slot, making it easy to locate, reducing idle time and fostering an environment conducive to precise 3D printing operations.

The Impact of Organization

An organized workspace stands as a silent testament to the operator's regard for safety. With everything in its rightful place, the chances of accidental trips or spills are minimized. Simultaneously, an orderly space provides room for enhanced focus. It streamlines the workflow, allowing for a smooth and seamless transition from one step to another. Imagine the 3D printing process as a graceful dance, where each step flows effortlessly into the next, unimpeded by misplaced items or clutter.

Pragmatic Steps towards Order

Begin by assigning a specific place for all tools and accessories. Use organizers or toolboxes to contain tiny components that can otherwise get lost or mixed up. Consider labeling compartments for ease of locating items. Furthermore, systematically store filaments, keeping them dust-free, properly sealed, and away from heat sources. Be strict about returning items back to their respective places after use, no matter how trivial the task might seem at that moment. The order must be nurtured and maintained for better outcomes.

In essence, organizing your workspace is not just a precautionary measure for safety; it’s an investment in efficiency, precision, and peace of mind. It ushers in a rhythm and flow that can make the intricate process of 3D printing less strenuous and more enjoyable. In this labyrinth, bringing order to chaos on your workbench is a critical step towards making your journey smoother and safer.

Emotional Connection

The journey through the land of 3D printing, as we have seen so far, is not without its perils. It's a terrain loaded with high temperatures, cluttered workspaces, and potential fire threats. But today, let's sidestep from discussing cautionary measures. Let's delve deeper into the emotional depths of this journey, to invoke within you a profound connection that strengthens your vigilant resolve towards 3D printer safety. Envision the electric thrill of watching your first creation come to life through a 3D printer. The exhilaration coupled with anticipation fills the air, much like the vivacious energy at a fairground. Imagine holding in your hands a physical manifestation of an idea that was just moments ago a mere figment of your imagination - an object sculpted in thin air, as if by some magical incantation. With every layer deposited, every line traced, you witness birth in its most sophisticated form. A moment like this can't help but forge an emotional bond between the creator, the machine, and the creation. However, in light of such awe and wonder, it becomes easy to overlook the potential risks involved in the process. You see, there's a bittersweet symphony playing here. Amidst the joys, there are also the sorrows - the discomfort of inhaling fumes, the sharp sting of accidental burns, and the overwhelming frustration when moving parts malfunction unpredictably. These harrowing experiences demand a sense of emotional resilience, a harmony of patience, diligence, and alertness. Now consider this. Every successful entrepreneur cherishes their initial failures, viewing them as invaluable learning experiences. Similarly, from the lens of a 3D printing enthusiast, each safety hiccup is an opportunity for growth. It shapes our mindset, encourages us to anticipate obstacles, and most importantly, instills in us a sense of prudence and responsibility. Wear these lessons like badges of honor, for they are symbols of your progress on this perilous yet thrilling journey. This emotional connection is essential to foster an understanding of the importance of safety in 3D printing, much like how fear conditions us to avoid placing our hand in a flame. It arouses a subconscious instinct to protect, making safety precautions not just an imposed routine, but a reflex action born out of care for oneself and one's craft. A personal connection with the subject fuels our drive to learn, adapt, and improve. When we emotionally invest in our actions, the struggle becomes personal, and a personal struggle never goes unresolved for long. The path to mastering 3D printer safety, like any other journey, is peppered with trials and triumphs. It's about maneuvering through difficulties while reveling in small victories. So, let's continue to unite caution with creation, shaping a safer and emotionally rewarding 3D printing experience.

Summarize Main Points

As we trace our journey through the labyrinth of 3D printing safety, it's beneficial to pause and reflect on the various dimensions we have navigated. The crux of this expedition lies in understanding the gravity of safety, infused with the awareness that 3D printing is not merely a fascinating leap into the future but also an odyssey fraught with potential hazards.

Our first encounter was with the must-have companion of any 3D printing adventure -- ventilation. This seemingly innocuous element shoulders the enormous responsibility of diffusing potentially harmful fumes emitted during the process. Operating in a well-ventilated area morphs from being a mere option to an indispensable necessity when working with hazardous materials like ABS or Nylon filament.

The next hurdle that dared to obstruct our path was the scorching heat generated by the printer's components. We understood the caution against direct contact until these components cool down. Any haste in dealing with these high temperatures can lead to painful burns, morphing an exciting endeavor into an unpleasant memory.

Electrical components and power supply are like the serpent hiding in the grass; silent but venomous. Handling these components with care, ensuring dry hands, and observing the cardinal rule of turning off and unplugging the device before making any adjustments was a lesson well drilled into our consciousness. These protocols channel electricity's raw power safely, avoiding any unfortunate shocks or accidents.

In an echo of childhood lessons, we learned to keep our fingers and loose clothing away from moving parts, guarding ourselves from hurtful surprises. Gears and motors, although animated with life, pose a risk of injury if not handled cautiously.

Material handling emerged as our next checkpoint. Using recommended filaments, complying with the manufacturer's guidelines, and understanding unique handling requirements— these practices all ensure we respect the intriguing world of 3D printing materials, keeping us safe in our interactions.

Even as we ventured further into this complex domain, we didn't lose sight of the potential fire hazard associated with electronic devices. We were reminded of the importance of ready access to a fire extinguisher, and the practice of not leaving the printer unattended for long stretches, especially during lengthy prints.

Last but certainly not least, organization proved to be our trustworthy ally. A cluttered workspace is a breeding ground for accidents, but ensuring clear spaces and properly stored accessories helps maintain an ordered environment conducive to safe and stress-free 3D printing operations.

Delving deeper into the emotional connection, it dawned upon us that our feelings toward the thrilling process of bringing creations to life are intertwined with the awareness of the potential risks involved. These emotions foster a sense of responsibility, reinforcing the importance of stringent safety measures and serving as a constant reminder to prioritize safety above everything else.

This retrospective walk-through underscores that while 3D printing may seem to offer an open invitation to the realms of innovation and creativity, it also demands careful navigation through risky landscapes. Adherence to safety guidelines doesn't just mitigate danger but also enhances the magical experience of witnessing our imaginations take form.

Restating the Thesis: An Uncompromising Emphasis on 3D Printing Safety

As we retrace our steps through the labyrinth of concerns regarding 3D printing safety, it becomes increasingly evident that an overarching sense of caution pervades every element of the printing process. The drive for conscientious practices, whether in ventilation, material handling, or maintaining a tidy workspace, has been the compelling heart of our discussion, reminding us of the necessity of undertaking this pioneering technology with a safety-first approach.

In reframing our thesis statement, we are not merely paraphrasing. Instead, we're taking a thoughtful pit stop to reassess and emphasize the enormous significance of safety in 3D printing. This technology, though ripe with promise, carries with it its own set of hazards: these range from intense heat generation and electrical risks, dangers looming in the printer's mechanical components, to the possibility, albeit rare, of fire hazards. It's a trail riddled with potential pitfalls and perils, which can only be traversely safely if we are armed with knowledge and a keen sense for precaution.

The essence of our discourse thus far, condensed into a single strand of thought, is this: Navigating the world of 3D printing is akin to traversing a path dotted with invisible hazards, where each step taken in ignorance increases the risk of a stumble. It emphasizes the importance of wearing the 'helmet' of knowledge and the 'shield' of caution while embarking on this journey. It serves as a timely reminder of our responsibility to minimize risks in the pursuit of innovation.

Every facet of 3D printing safety we've engaged with underscores the need for a thoughtfully planned, carefully executed strategy. By tackling each hazard head-on, acknowledging its presence, and finding ways to mitigate it, we stand a far better chance of enjoying the manifold benefits of 3D printing without falling victim to its dangers. In essence, the saga of 3D printing safety is one of diligence and vigilance—of knowing when to pause, assess, and ultimately make informed decisions for the sake of safety.

As we move forward to the remaining sections of our guide, let's bear in mind this resounding message: Navigating the perilous path of 3D printing safety isn’t a mere suggestion—it’s an imperative. Only by remembering this can we hope to fully unlock the potential of this revolutionary technology while ensuring our safety and the safety of those around us.

Leaving a Lasting Impression

As the journey of delving into the intricate world of 3D printing comes to its close, the depth, the complexity, and the sheer wonder of this technology should hopefully remain etched in your memory. Yet, while the allure is undeniable, it is my hope that you also take away a profound sense of responsibility. Remember, the realm of 3D printing, fascinating as it is, is not free of peril. One cannot overstate the importance of safety practices in 3D printing. Think about it. It is more than just a protocol or a checklist to tick off before proceeding. It’s akin to the seatbelt we fasten every time we're behind the wheel, the safety goggles we wear at the chemistry lab, or the helmets we don when we ride. Just as these measures protect us from unforeseen accidents, the safety guidelines we adhere to in 3D printing shield us from potential harm. The beauty of 3D printing lies not only in its vast possibilities but also in the assurance that with prudent use, we can navigate its valleys and peaks without harm. We are explorers setting foot into unknown territory armed with the best tool possible - knowledge. Imagine yourself as a master conductor of an orchestra, leading the symphony of innovation. The 3D printer is your ensemble of musicians, each part having a unique role to play - the filament, the heated bed, the extruder, the stepper motors. And like any great conductor, you must ensure that every element works harmoniously, and safely, to create marvels out of thin air. 3D printing can feel daunting, maybe even intimidating. But remember, every expert was once a beginner. With every trial and error, with every triumph and misstep, we learn, we grow, and we evolve. A fantastic architectural edifice wasn't erected in a day. It took time, patience, and an unwavering commitment to safety standards. Now that you are armed with this knowledge, engage with 3D printing like never before. Create, innovate and find joy in the transformative power of this technology. But always prioritize safety. That is the foundation on which the grand edifice of innovation stands. As we end, it’s worth reflecting upon a quote from Ralph Waldo Emerson - "The creation of a thousand forests is in one acorn." Imagine what could be created by a single 3D printer in your hands - a thousand prototypes, a thousand designs, a thousand solutions. But with this incredible power comes an innate responsibility to wield it safely. As you embark on this journey, let the thrill of innovation not blind you to the path of safety. Let every print you create not just be a testament to your creativity but also a tribute to your commitment to safety. Because at the end of the day, the greatest masterpiece is ensuring that the journey of creation is safe, secure, and fulfilling. END OF SECTION

Additional Safety Tips

Tread lightly into the vibrant labyrinth of 3D printing, for there are still many unsung safety melodies and cloaked dangers often overlooked. Let's explore a few additional precautions that stand as potent guardians in the world of 3D printing, vital sidekicks to those already discussed.

Add Protective Gear to Your Arsenal

One might think of being an artist of the third dimension like a modern-day knight, heading into battle with the dragon of creation. The gleaming armor of precaution is quintessential. Just as a knight would not dream of facing a dragon without a shield, neither should a 3D printer user embark on their journey without proper protective gear. Depending on the material you're working with, a basic mask, goggles, and gloves can act as invaluable companions in your saga of creativity, guarding against unwanted particles or potential mishaps.

Regular Maintenance: Your Magic Elixir

Imagine the sorcerer's stone, an artifact of grandeur, but what if it were left unattended? Over time, its gleaming allure might fade, succumbing to the wear of age. Our printers, though not mythical artifacts, are no different. Routine maintenance of your printer ensures that it remains at peak performance, reducing unforeseen risks. Check your printer regularly for signs of wear or damage and replace parts as necessary. A well-maintained printer is akin to a finely tuned symphony, each part playing its role to perfection, ensuring a harmonious and safe operation.

The Silent Serpent: Noise Pollution

In the world of 3D printing, danger does not always make itself known through visible sparks or tangible heat. Sometimes, it lurks in the shadows, wearing the guise of incessant noise. The continuous operation of a 3D printer often leads to high decibel levels, which can gradually lead to hearing discomfort or potential damage over time. This silent serpent can be tamed through the use of ear protection or by ensuring the printer is situated in a separate room or area where the noise will cause minimal disturbance.

Beware: The Bewitching Lure of Modifications

The prospect of modifying your printer to maximize its capabilities might seem as enticing as a siren's song. Beware, for here lies a path fraught with unforeseen peril. While enhancements can amplify the performance of your printer, they could also potentially void your warranty or compromise safety measures. Always tread carefully in these promising but precarious waters. Before embarking on any modifications, factor in the pros and cons, ensuring that safety never takes a backseat to ambition.

In the dynamic world of 3D printing, these supplementary safety tips act as gentle whispers of caution amidst the euphonious orchestra of creativity. They remind us that while we are bold explorers, voyaging through the realms of creation, we must respect the inherent risks attached. So, remember, in your quest to master 3D printing, don't rush headfirst into the labyrinth; instead, equip yourself with this comprehensive guide to safely navigate the intricate maze of 3D printing.

Future Developments in 3D Printing Safety

As we stride confidently into the future, exploration continues to redefine boundaries and technological advancements enable us to re-imagine the paradigm of 3D printing safety. Encouragingly, we find ourselves at the cusp of some exciting potential developments that promise to transform our approach to ensuring safe 3D printing practices.

Enhanced Monitoring Systems and Sensors

The increasing integration of smart technology is one of the key trends shaping the future of 3D printing safety. For instance, sophisticated monitoring systems armed with advanced sensors are forecasted to become mainstream. These systems would detect temperature aberrations, filament inconsistencies, and any other operational anomalies. As a result, they could preemptively identify potential hazards, thereby enhancing overall safety. This kind of automation, akin to a vigilant sentinel standing guard, seems plucked from the pages of a futuristic novel. Yet, it promises to be an achievable reality in the near future.

Improved Ventilation Solutions

The issue of ventilation, a critical aspect of 3D printing safety, is also expected to witness groundbreaking progress. Researchers are exploring innovative solutions that may include built-in ventilation systems or specialized enclosures for 3D printers. Imagine a 3D printer encapsulated within its own eco-friendly bubble, effectively trapping and neutralizing harmful fumes. This sort of development could revolutionize safety protocols and significantly mitigate health risks associated with 3D printing.

Advancements in Filament Technology

The materials we use in 3D printing, known as filaments, are also undergoing continuous evolution. In the future, we might see a surge in the use of filaments designed specifically with safety in mind – bio-compatible materials, non-toxic plastics, or even filaments equipped with self-extinguishing properties. This progress doesn't merely represent an incremental improvement; it's akin to reinventing the wheel itself, by transforming something fundamental to the 3D printing process.

Education and Training

Alongside physical advancements, the future of 3D printing safety also hinges on enhancing our collective consciousness about safety norms. Thus, continued emphasis on education and training is imminent. We could see more comprehensive safety guidelines, resourceful online platforms, easily accessible tutorials, and even virtual reality-based training modules. Imagine strapping on a VR headset and learning to handle a 3D printer in a simulated environment, where mistakes come without real-world consequences. This suggests a promising avenue for making safety education more immersive and effective.

As we peer into the crystal ball of the future, it's exhilarating to envisage the transformative developments that lie ahead in the realm of 3D printing safety. The convergence of technology and research offers fascinating potential to not just improve, but redefine safety measures. By embracing these advancements, we can ensure that our journeys through the intriguing world of 3D printing remain safe, enjoyable, and enlightening. END