The Tale of the UPbox+ Resurrection

The Tale of the UPbox+ Resurrection

In the bustling heart of the Innovation Lab, ten UPbox+ 3D printers lay dormant, their print beds as bare as a barren desert. The air buzzed with anticipation as the team prepared to breathe new life into these mechanical marvels. The task was straightforward yet meticulous, demanding both precision and patience.

Embarking on the Journey

Our quest commenced with an internal cleaning. Each machine was carefully opened, revealing the innards coated with accumulated dust and stray filament strands. Eyes narrowed in concentration, we delicately removed each fragment, ensuring every component gleamed. The significance of this step was paramount; pristine components mean optimal performance.

The exteriors weren't neglected. We wiped down each printer, transforming them from a dull, dust-laden state to a radiant, renewed shine. Our task wasn't just about functionality; the aesthetics played a role in inspiring students to engage with these tools.

The Heartbeat Restored

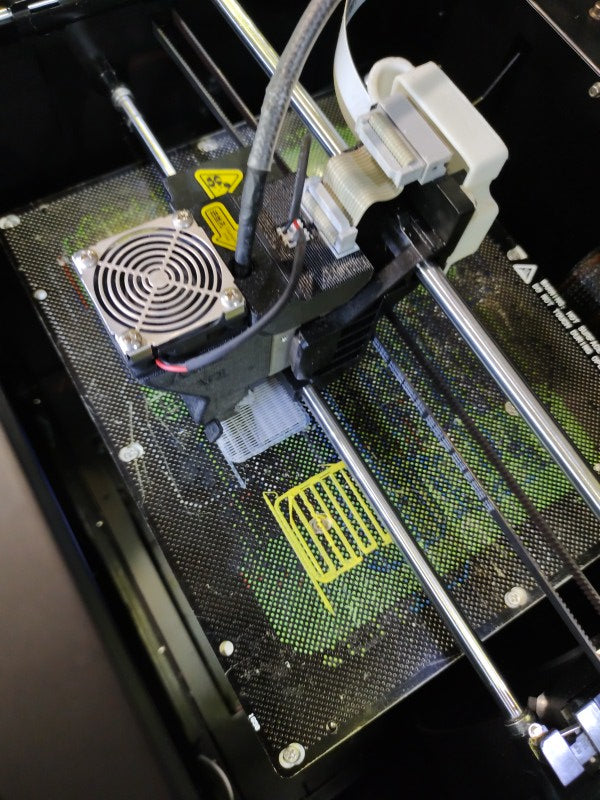

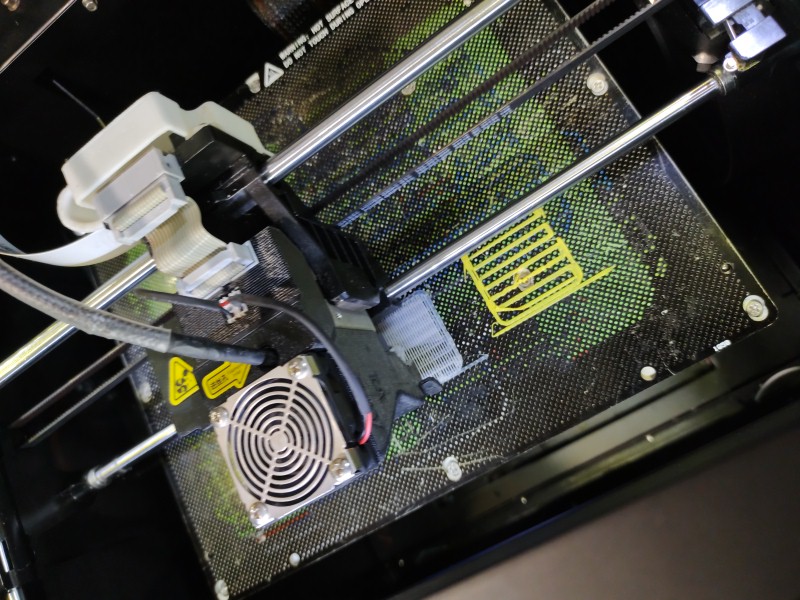

With the machines clean and polished, it was time for the rigorous diagnostic run. Each printer hummed to life, undergoing a battery of tests that confirmed the seamless operation of all components. Print quality was scrutinized with a keen eye, ensuring the final products met impeccable standards.

The bed calibration was the final yet crucial hurdle. A level print bed is the cornerstone of successful 3D printing. Misalignments can spell disaster, leading to print failures or imperfections. We painstakingly calibrated each bed, ensuring a smooth and even printing surface.

The Culprit Unmasked

But the tale took a darker turn at the eighth machine. Initially, it appeared unscathed, giving no external signs of distress. It was only when we pressed for a test print that a dissonant 'click-click' reverberated through the room. Intrigued and mildly alarmed, we traced the sound back to the plastic extruder, which to our dismay, had succumbed to damage.

The elderly extruder, drained by hours of relentless printing, had reached its final curtain call. It was fatigued and cracked, no longer able to propel filament with the vigor required. Our remedy? Replace it with a metal extruder—a true knight in shining armor, known for its resilience and fortitude.

The Triumph

Upon installing the metal extruder, we opened the hot end and cleaned it thoroughly, removing any residual material that could hinder performance. The meticulous maintenance concluded with successful material extrusion and precise bed leveling. Each UPbox+ printer was revived and rejuvenated, standing as sentinels ready to assist students in their creative quests.

Four hours flew by like mere moments. The dazzling gleam of the printers mirrored the team's satisfaction. The UPbox+ machines, once silent and lifeless, now buzzed with potential, ready to inspire and empower the young innovators of tomorrow.