Solving the Clicking Conundrum of Paul's Creality Ender3

In the world of 3D printing, persistence, and patience are virtues. But sometimes, they're met with challenges that call for technical intervention. Such was the case with Paul's printer—a Creality Ender3—that, despite his efforts, refused to print, responding only with a persistent 'clicking' noise.

Paul, concerned and a bit frazzled, came to us with his treasured machine. The sound of a 'click' where the hum of printing should be is often the telltale heart of a 3D printer's distress call. Determined to restore Paul's printer to its former glory, we were on the case.

Upon a cursory examination, the printer gave no external signs of distress. It was only when we attempted a test print that the 'clicking' symphony began. Following the sound to its source, we found the villain of our story—the plastic extruder. Despite its duty of guiding filament to the hotend, it had succumbed to damage. A common fate for extruders after enduring many hours of printing, it was no longer capable of performing its essential function.

The extruder, especially in machines like the Ender3, experiences constant pressure as it pushes filament through the printer's heart. When made of plastic, the extruder is vulnerable to wear and tear that can manifest as cracks or breaks under the strain. Such was the fate of Paul's extruder, which upon inspection, showed signs of fatigue and damage.

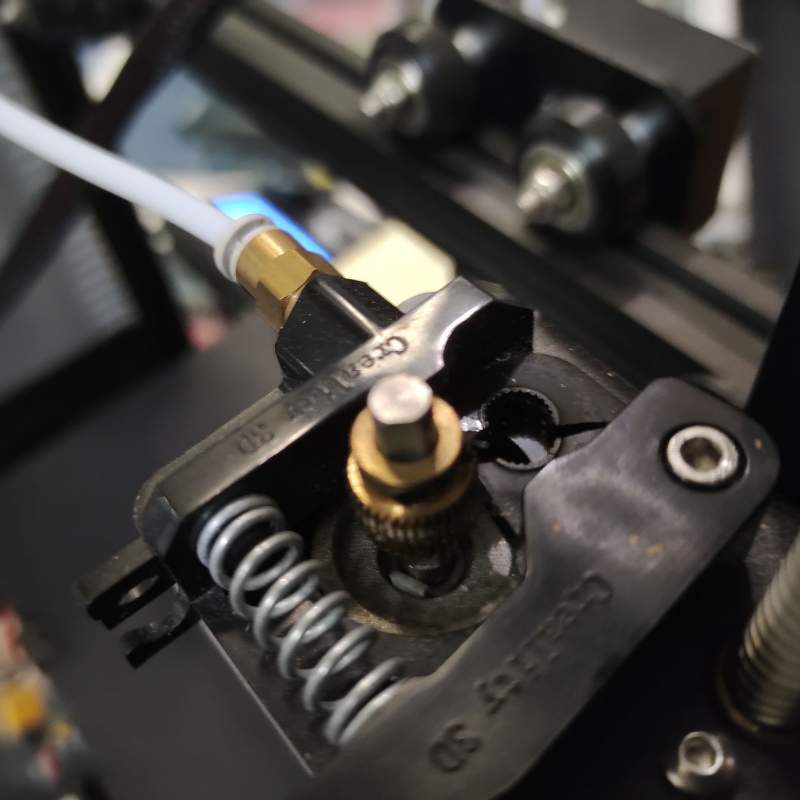

Understanding that a durable solution was needed, we decided to upgrade Paul's printer with a metal extruder. This isn't just a replacement; it's an enhancement. Metal extruders are known for their resilience and longevity, able to withstand the high pressure of printing without buckling under the strain.

With surgical precision, we replaced the faltering plastic part with its new metal counterpart. The installation was meticulous, ensuring every component aligned perfectly for optimal performance. Once fitted, it was time for the moment of truth. We initiated a print, and the 'clicking' was no more. In its place was the smooth operation of the printer, doing what it was designed to do—create.

Paul's reaction to the resurrected printer was priceless. The satisfaction of seeing his Ender3, once silenced by damage, now printing flawlessly, was all we needed to mark this case 'closed.'

In the end, the repair was not just about fixing a part but about understanding the printer's needs and responding with a solution that would extend its life and reliability. It's cases like these that reinforce our philosophy at 3D Printing Perth: to offer repairs that not only fix but also improve. As Paul left, his departure was the quiet after a successfully solved problem, the best music to our ears.