Navigating the Nuances of 3D Printer Cable Replacement: A Technician's Perspective

When it comes to the intricate world of 3D printer repair, not every task is as straightforward as it seems. This was exemplified when Sam walked into our shop with his Anycubic 3D printer. He requested a seemingly simple service: to have the cable for the heated bed replaced, and he had brought his own replacement cable for the task.

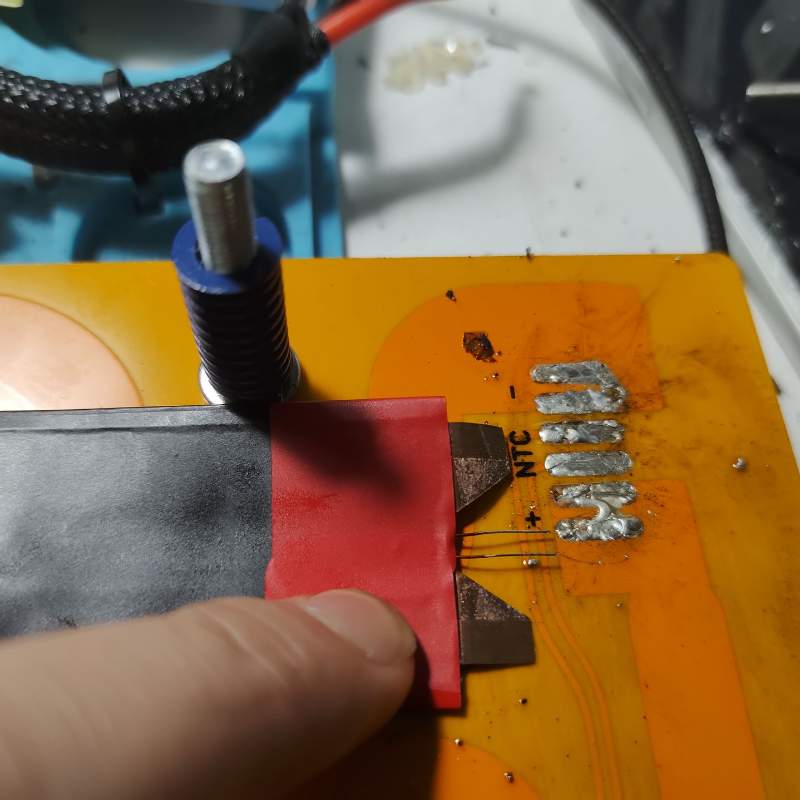

Our first step was to remove the old cable, a process that involves careful desoldering to avoid damage to the heat bed’s delicate electronic components. The operation requires a steady hand and an understanding of the precise temperature needed to melt the solder without harming the surrounding parts. Once the old cable was successfully detached, we were ready to proceed with the installation of the new one.

However, as we positioned the new cable for soldering, we encountered an unforeseen obstacle. The cable provided by Sam was not the perfect fit we were anticipating. One of the connector's screws collided with the cable's path, creating an alignment issue that made it impossible to attach it securely to the heat bed. In the world of 3D printing, precision is paramount, and even a minor misalignment can lead to significant failures, from uneven heating to potential fire hazards.

Our team was faced with a decision: to proceed with an ill-fitting component, risking the printer's functionality and safety, or to revert to the original configuration. With our client's best interest in mind, we opted for the latter. Ensuring the safety and reliability of a repair is always our top priority, and this situation was no different.

We re-soldered the original cable back into place, ensuring that the heat bed was restored to its prior state. It's always our goal to provide solutions, but sometimes the right solution is to maintain the status quo, especially when the alternative could lead to further complications.

This encounter serves as a valuable lesson that not every job can be completed as planned, particularly when it comes to specialized equipment like 3D printers. The specificity of parts and the preciseness required for these machines often mean that third-party components may not always be suitable for a straightforward swap.

In conclusion, Sam's Anycubic Printer left our shop in the same state it arrived, not due to a lack of expertise or effort, but because our commitment to quality and safety is unwavering. While we couldn't fulfill the initial request, we stood by our principles, ensuring that Sam's 3D printing ventures could continue safely. As technicians, we understand that the path to the right solution is sometimes about knowing when not to proceed.