Demystifying Joe's Creality CR-10 Printing Woes

In the meticulous craft of 3D printing, the line between a masterpiece and a mess can be as thin as a filament strand. This was precisely the challenge faced by Joe with his Creality CR-10. He came to us with a problem that's all too familiar in our line of work: failed prints that turned into a tangle of wasted filament sprawling across the print bed.

Joe's description of the issue was vivid—each attempted print resulted in what he termed "waste wire," a chaotic accumulation of filament rather than the desired object. It's a frustrating issue that can have a plethora of causes, from improper bed leveling to incorrect temperature settings.

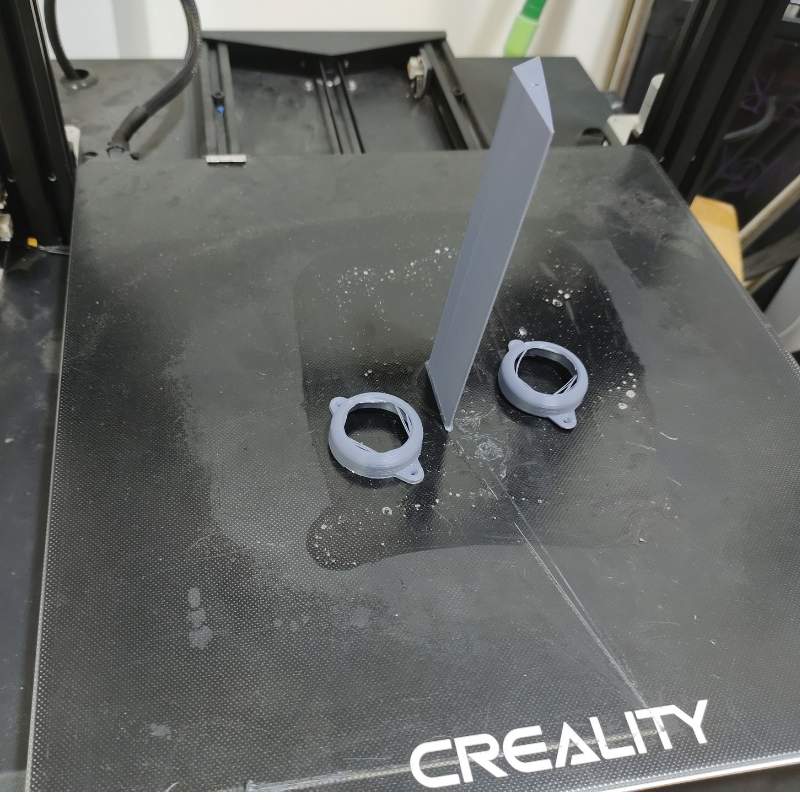

When Joe's printer arrived in our workshop, we initiated a series of test prints to replicate the problem. We started with small-scale objects, which the CR-10 managed to print without a hitch. Perplexed but not defeated, we scaled up, printing larger items to test the printer's limits. Surprisingly, the larger prints also came out flawlessly, leaving us to ponder the cause of Joe's printing predicaments.

The CR-10, a printer lauded for its reliability and quality, was not at fault here. This led us to a crucial aspect of 3D printing that's often overlooked: user error. The printer's settings are paramount; they need to match the intricacies of the design, the type of filament used, and the printer's capabilities.

We sat down with Joe and walked him through the basics and nuances of setting up a print job correctly. We discussed bed leveling, which ensures the first layer sticks perfectly. We talked about temperature settings, which vary depending on the filament—too hot, and the filament oozes; too cold, and it won't adhere. We covered print speed, which needs to be adjusted based on the object's complexity and size. And, importantly, we emphasized the significance of slicer settings—those myriad of tweaks in the software that translates a 3D model into a language the printer can understand.

Equipped with new knowledge and a checklist of optimal settings for his printer and filament, Joe was ready to take another stab at printing. The printer, which had never faltered in our care, was now set up to succeed in Joe's as well.

As Joe left, the air was filled not with the smell of wasted filament but with the promise of successful prints. His parting smile was a sign of a customer not just satisfied with the service but empowered with the knowledge to prevent future failures.

This experience underscores a vital message for all 3D printing enthusiasts: the power of a printer lies not just in its mechanical capabilities but equally in the user's understanding of how to harness those capabilities. It's a dance between man and machine that, when in sync, produces objects of beauty and utility.