Case Study: The Challenge of a Severely Clogged 3D Printer Nozzle

Introduction:

The magic of 3D printing lies in its ability to transform a spool of filament into intricate objects. However, like all machinery, 3D printers are not immune to operational hiccups. At 3D Printing Perth, we often encounter various printer issues, but one recent case stands out due to its severity and the satisfaction derived from its successful resolution.

The Customer's Dilemma:

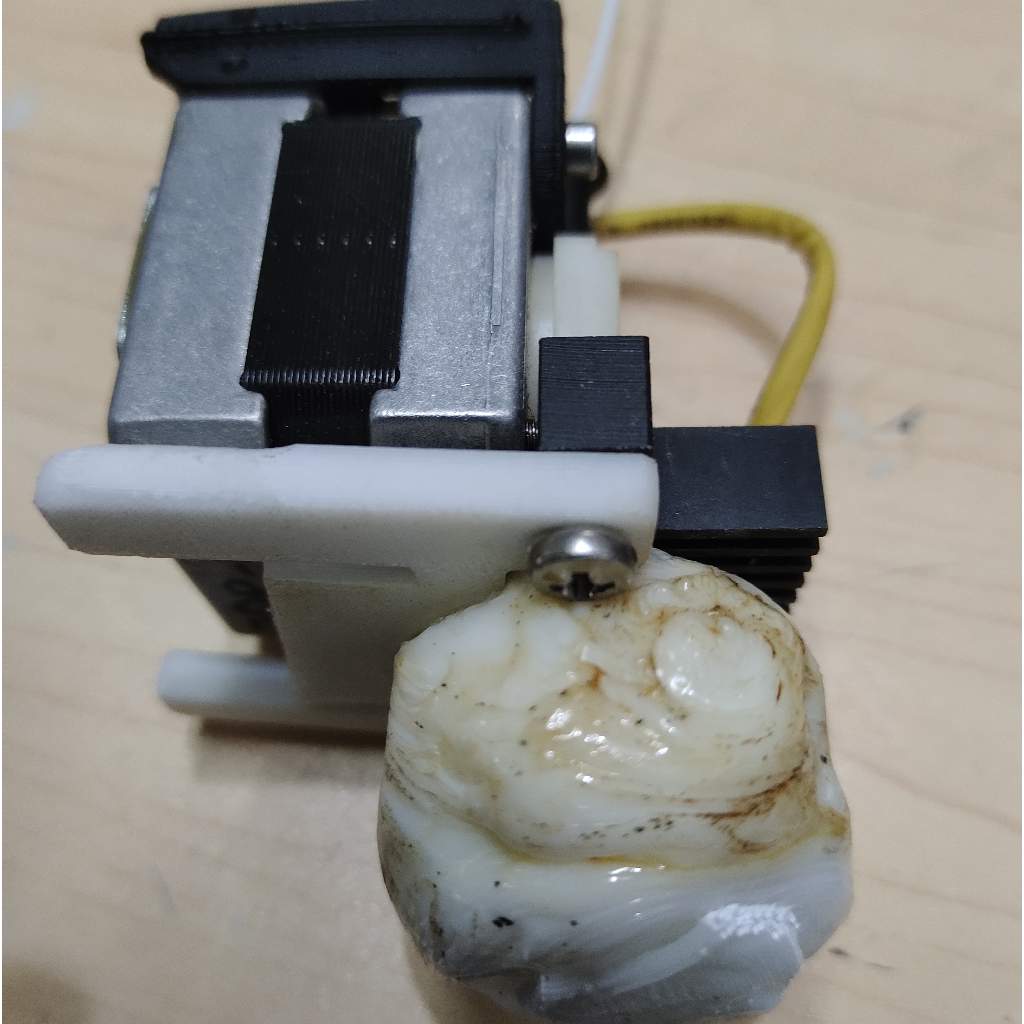

One sunny afternoon, a customer entered our store with a sense of urgency. Clutched in their hand was a part of their 3D printer - the extruder assembly. At first glance, the problem was evident. Where the sleek nozzle tip should have been, there was an oversized, hardened bulb of filament. The nozzle was not just clogged; it was engulfed.

The customer explained their predicament. Midway through a print job, the printer stopped extruding filament. On inspection, they discovered the massive glob of filament around the nozzle. Uncertain about how to tackle this unprecedented issue and worried about potentially exacerbating the problem, they turned to us for expert assistance.

Analyzing the Problem:

A clogged nozzle can be a common issue for 3D printing enthusiasts. Still, this was an extreme case. Filament can sometimes over-extrude or not adhere correctly, leading to accumulation. Typically, these are small blobs or strings. However, in this case, the accumulation had grown unchecked, leading to a significant blockage.

Why did this happen? Several factors could lead to such an issue:

Incorrect Temperature Settings: If the filament's temperature isn't optimized, it can either melt too much or not enough, leading to over-extrusion or improper adhesion.

Filament Quality: Lower quality filaments can have impurities that cause inconsistent melting or lead to nozzle obstructions.

Infrequent Maintenance: Regular cleaning and maintenance of a 3D printer are crucial. Over time, residue can build up inside the nozzle, leading to blockages.

The Solution Process:

With a clear understanding of the problem, our team embarked on the repair mission. The steps were methodical:

Disassembly: We began by carefully disassembling the extruder to gain comprehensive access to the clogged nozzle.

Removal of Obstruction: Using precision tools, we chiseled away at the hardened filament. This process required patience and care to ensure the nozzle and surrounding parts remained undamaged.

Deep Cleaning: Once the bulk was removed, we conducted a deep cleaning of the nozzle. This was to ensure that no minute residues remained that could cause future blockages.

Reassembly and Testing: After cleaning, the extruder was reassembled. Before handing it back, we ran several test prints to ensure the printer was functioning optimally.

Happy Endings:

The printer, once choked by the filament mass, now operated smoothly, churning out flawless prints. The customer, who had watched the entire process, expressed their immense relief and gratitude. They confessed their limited knowledge about the intricate workings of their 3D printer and vowed to be more vigilant about its maintenance in the future.

Before leaving, they settled their bill, their demeanor now noticeably lighter than when they had walked in. As they exited with their rejuvenated printer, our team shared a collective sense of accomplishment.

Conclusion:

This case serves as a reminder of the complexities inherent in 3D printing. While the technology is undoubtedly transformative, it requires care, understanding, and, occasionally, expert intervention. Regular maintenance and a keen eye for anomalies can prevent most issues. But when things do go south, knowing there's a reliable service provider to turn to can make all the difference. At 3D Printing Perth, we're always ready to rise to such challenges, ensuring our customers' printing journeys remain smooth and fulfilling.