Ankermake 3D Printer Adventure

The Resurrection of the Ankermake 3D Printer

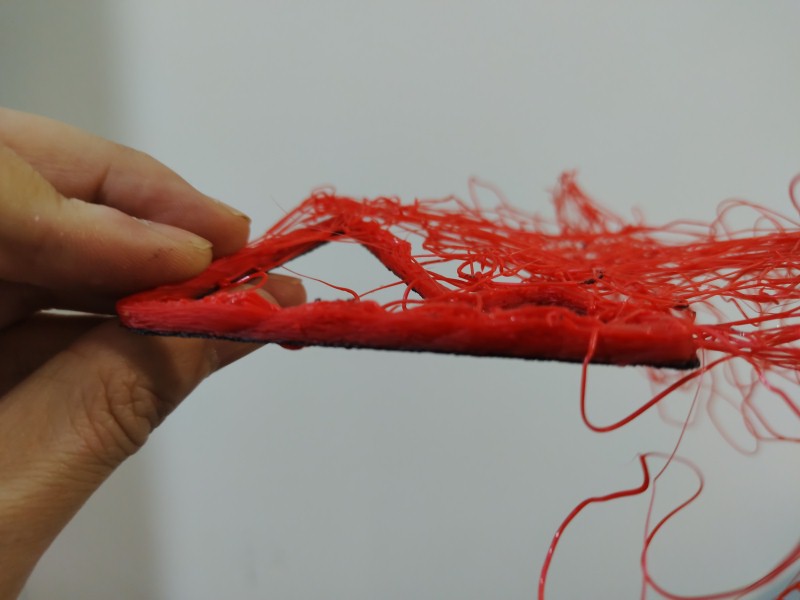

In the dim light of a cluttered workshop stood an Ankermake 3D printer, downcast and defeated. For months, it had produced nothing but frustration—after a few layers, the prints would devolve into a chaotic mess of filament, detaching from the bed and ruining countless projects.

Jack, the devoted owner, could no longer ignore the persistent issues. Determined to unearth the source of the printing failures, he dove into a meticulous dissection of the beleaguered machine. With careful hands, he deconstructed the printer piece by piece, each step revealing layers of potentials, yet dismissing them one by one until the clue was found. The X-axis railway—it was not secure and not in the right spot.

This revelation rung a bell of recognition among the team; misalignment in the X-axis could wreak havoc on prints, causing them to detach from the bed, leading to what seasoned 3D printing aficionados grimly refer to as "spaghetti prints." The hotend, swaying like a tightrope walker's stick, had been disrupting the balance crucial for printing.

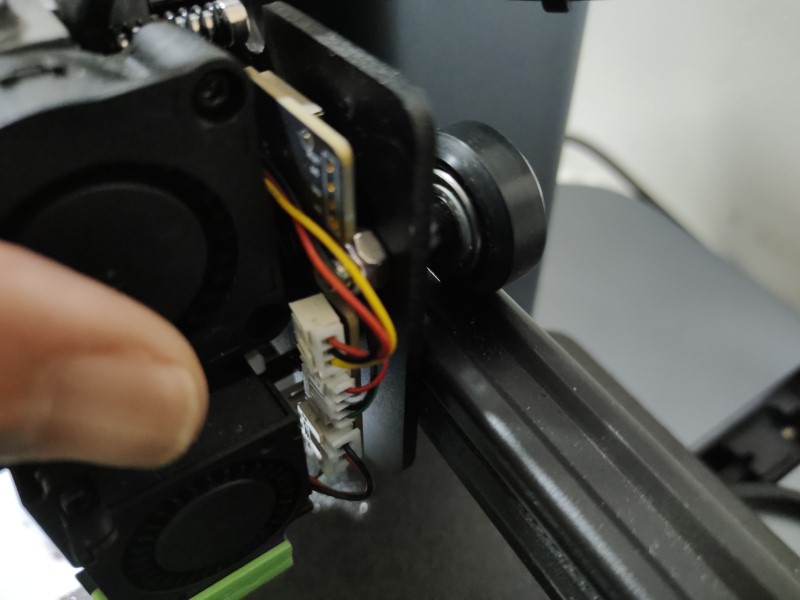

The task at hand was straightforward yet delicate: disassemble the hotend railway, realign it, and secure it back into place. With screws falling into neat little trays and sides laying bare, the team gently extricated the errant components. Each member, armed with their tools, approached the task with a mix of precision and care, ensuring not to exacerbate the fragile situation.

When the railway was finally liberated from its misaligned constraints, a sense of optimism filled the room. Realignment was no trivial matter; it required a blend of mechanical dexterity and an almost instinctual understanding of the machine's needs. The hotend was smoothly realigned and affixed with the utmost precision, each screw securing a calculated fraction of a millimeter.

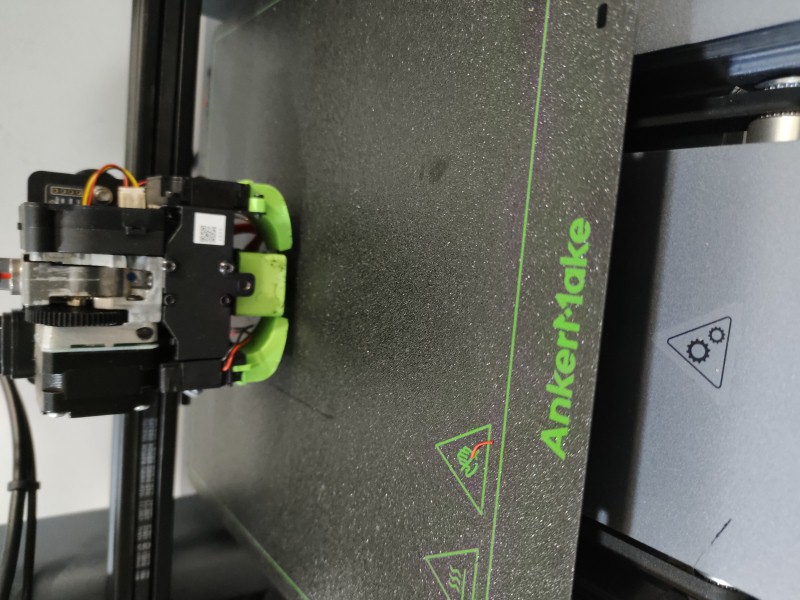

Reassembly took less time than the dissection. With the final screw turned tight, the Ankermake stood tall once more, a mechanical phoenix ready to prove its worth anew. But before it could be labeled "fixed," it had to pass the ultimate test: printing.

The atmosphere in the workshop was tense as they initiated the test print. The familiar whirring and clicking noises filled the room, but this time there was a smoothness to it, an indication that things were aligning as they should. Layer by layer, the print grew, revealing the telltale lines of a job well done.

After what seemed like an eternity, the print completed, detached flawlessly from the bed, and stood as a testament to problem-solving and determination. Cheers and sighs of relief echoed through the workshop; the Ankermake was back in action. It was a victory not just over malfunction, but a triumph of dedicated perseverance and technical acumen.

Jack could now look forward to the promise of countless successful prints, all thanks to the love and attention lavished upon his trusty Ankermake. This machine was not just a tool; it was a vessel of dreams, now ready once more to turn filaments of plastic into masterpieces of imagination.