3D Printer Repair Story

Creality Ender 3: A Misaligned Adventure

Ken had always been proud of his Creality Ender 3. This trusty 3D printer had been with him through countless projects, turning digital dreams into tangible reality. However, one fateful evening, the very heart of his creative space seemed to betray him. Instead of the familiar hum and precise layering, Ken's printer produced nothing but frustration. It was clear the machine was not printing correctly. Ken noticed that the belt was running in the wrong direction and the bed wasn't adjusted properly. A quick look at the tangled mess of wires didn't help either. He was at a loss.

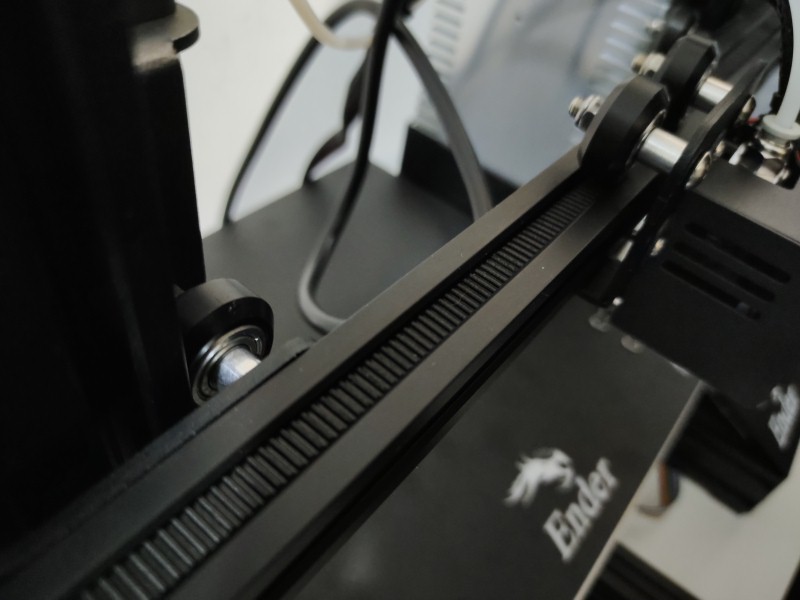

Determined to get to the bottom of the issue, Ken decided to seek professional help. Enter our team of 3D printing specialists. When we arrived, the first thing we noticed was the chaotic belt direction. It was clear that the belt would need to be completely removed and reassembled in proper alignment. This wasn't just a swap-out job; it required a keen eye for alignment and tension to ensure the belt moved harmoniously with the pulleys and the motor's rhythm.

Carefully, we disassembled the affected components. Step-by-step, the belt was reinstalled correctly, ensuring each connection was secure and properly aligned. Once the belt was taken care of, we turned our attention to the bed. Removing the bed from its frame, we adjusted it meticulously, making sure it lay perfectly flat. We then reconnected all the wires, ensuring they wouldn't obstruct the bed's movement.

With everything back in place, we initiated a test print. The transformation was like night and day. Where there had once been misalignment and failure, there now was smooth operation and precise layering. The Ender 3 was back to performing as expected, gracefully churning out projects with the meticulous detail it was known for.

Ken’s relief was palpable as he watched his printer lay down perfect layers, one after the other. His smile was a testament to the success of our repair. It's in these moments we are reminded of the importance of our work—helping creators like Ken bring their ideas to life without the frustration of mechanical setbacks.

This case underscores a valuable lesson: the smallest components often play pivotal roles in the functionality of complex machinery like 3D printers. Regular maintenance and timely repairs are crucial. For Ken, this experience was a reminder that sometimes, a little professional help can go a long way in ensuring the smooth operation of his 3D printing endeavors.