Selling fast!

Get yours while you can.

$2.20

Couldn't load pickup availability

Secure your shopping experience with various safe and trusted payment methods.

Hotend Throat make a pathway for filament go from cool zone to hot zone, The inner size for insert filament must be perfect fit for the filament you are using, the inner hole is too big, the filament will jam on the hot zone, the filament will not be able to come out from the nozzle. The throat come with different size, different length, different size thread, all metal or with PTFE tube. Different type of the throats has different usage. The throat, hot block and nozzle must be secure tight to make sure the melted filament will not be able to come out from the gap between the throat and nozzle.

The Throat with PTFE tube means the PTFE tube inside of the metal throat, The advantage of using PTFE tube is making filament moving smoothly and easily, which is good for PLA Filament. But the disadvantage for PTFE tube is the limitation for the temperature. You cannot set the temperature too high, otherwise the PTFE tube will melt and sticky and make the hotend jammed.

The Throat with All metal means the throat was fully metal which support higher temperature. All metal throat is good for higher temperature filament such as ABS, PETG, Carbon fibre. Etc.

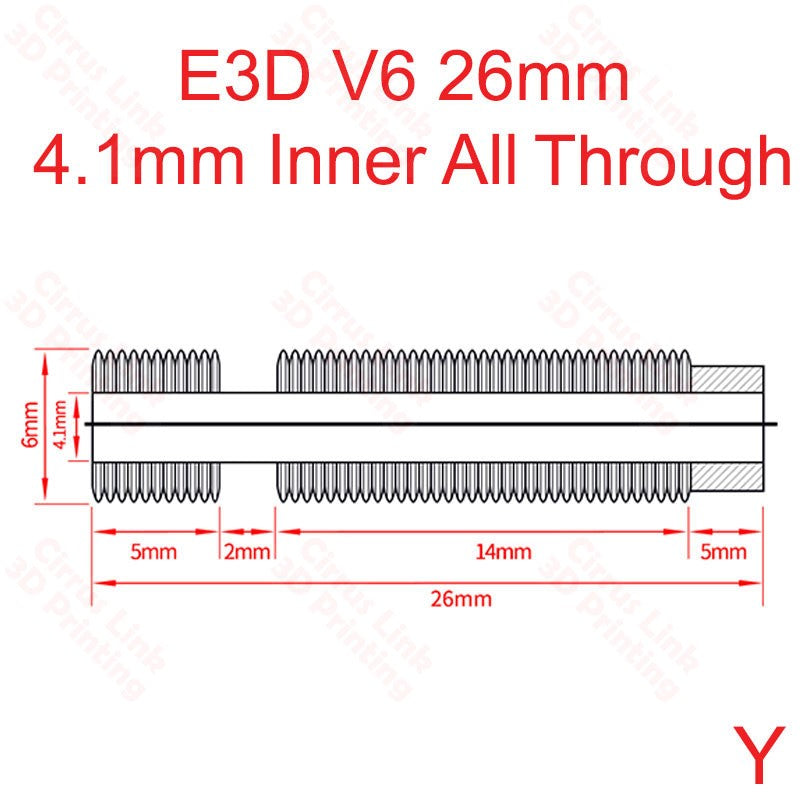

This Threaded E3D V6 throat is for 1.75mm filament. And it made from good quality stainless steel. 45° degree on the insert area, make sure filament loaded properly and smoothly.

Specifications:

Quantity : 1

Material: Stainless steel

For 3D Printer 1.75mm Extruder; E3D V6

Radiating end: M6

Heating end thread: M6

|

|

W |

X |

Y |

|

Length |

26mm |

26mm |

26mm |

|

Type |

All Metal |

With PTFE Tube |

4.1mm All Through |

At our Shopify store, we prioritize your safety and security. Here's how we ensure a secure shopping experience:

1. Secure Transactions: We use advanced encryption to protect your personal and payment information, ensuring it is safely transmitted and safeguarded.

2. Trusted Payment Gateways: Our store integrates with trusted payment gateways, ensuring your transactions are processed securely and efficiently.

3. Data Privacy: Your privacy is our top priority. We follow strict data protection policies to keep your personal information confidential and secure.

4. Secure Platform: Shopify provides robust security features and continuous monitoring against vulnerabilities, ensuring a safe shopping environment.

5. Verified Merchants: We are a verified merchant on Shopify, committed to providing authentic and high-quality products.

6. Transparent Policies: Our clear return, refund, and shipping policies provide peace of mind, knowing we stand behind our products.

7. Customer Support: Our dedicated customer support team is ready to assist with any concerns or questions you may have.

Shop confidently at our Shopify store, where your safety and satisfaction are our top priorities.

$2.20

Selling fast!

Get yours while you can.