The K1 MAX Adventure: Untangling the Filament Fiasco

The K1 MAX Adventure: Untangling the Filament Fiasco

In the cozy confines of his workshop, Ethan stood perplexed, staring at the Creality K1 MAX, a steadfast companion in his 3D printing journey. This wasn’t his first encounter with the beast, but today, it refused to dance the digital tango they had perfected over numerous print jobs. It was the printing expedition of July 2025, and the situation was dire.

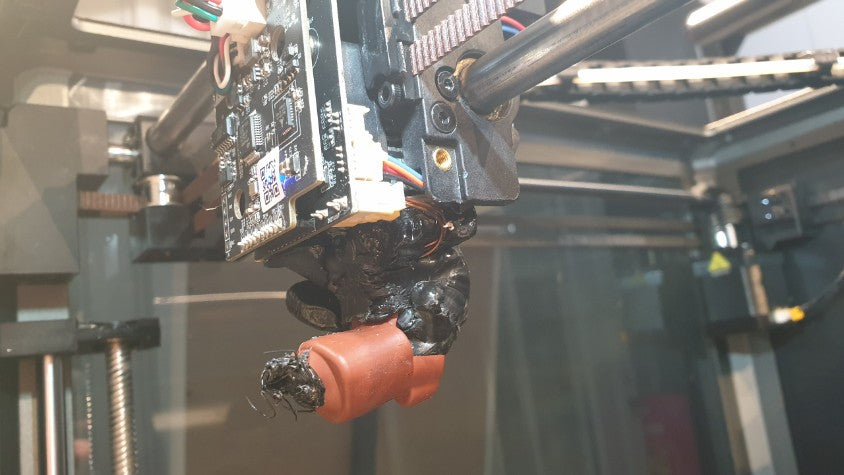

The problem was blatant yet puzzling: a chaotic ball of filament had formed right at the nozzle, wrapping its sinewy filaments around the print head like an alien cocoon. Instead of the graceful layers of a burgeoning creation, Ethan found himself facing the hardened sculpture of filament waste.

Ethan, accustomed to his printer’s quirks, checked the basics. Filament loaded? Check. Model file correct? Check. Nozzle temperature? Optimal. Everything seemed in order yet the problem persisted, like a small hiccup in an otherwise perfect symphony. It was time to delve deeper, peeling back the layers of this filamentous misadventure.

What could have caused such rebellion from his trusty apparatus? He pondered as he unplugged the unit for a more in-depth exploration. The answer was tangled right in front of him: the filament, in its heated journey through the nozzle, had turned rebellious, refusing to adhere to the print bed, and instead had curled and congealed into a ball.

With the precision of a trained technician, Ethan embarked on cleaning the kludgy mess. Using pliers, he gently pried away the layers of filament that clung to the nozzle, each strand a testament to the turmoil within. The K1 MAX had turned into a dragon, overwhelmed by its own fiery breath. Slowly, but surely, the clump surrendered, the gleaming nozzle once again visible beneath the polymer shell.

With a deep breath, Ethan reassembled his mechanical partner, ensuring each part was snug and as it should be. He powered it back on, hopeful and perhaps a smidge wistful, as the familiar hum re-emerged, filling the room with electric optimism. The K1 MAX, relieved of its filament burden, sprang back to life, extruding smoothly, faithfully reverberating its rhythmic harmony.

Thus, Ethan’s K1 MAX was restored, ready to forge its next tactile masterpiece. The incident, though an unexpected hindrance, fortified the bond between Ethan and his machine. He now harbored a newfound appreciation for the intricacies of maintenance, understanding that even the best of technology needed a little TLC to stay in perfect sync.

This experience served as a reminder: every clog is an opportunity for resolution, every filament ball a lesson in patience. For Ethan and his K1 MAX, the journey continues, replete with challenges, triumphs, and endless creation.